One negative side effect of a turbocharger is that when you compress air, it heats up. The temperature of the discharged air from a turbo can exceed 500°F (at higher boost levels). Rising temperatures also result in a drop in air density. One popular way of combatting this is with the use of an intercooler.

Air-To-Air Heat Exchanger

Intercoolers (which can also be referred to as an aftercooler or charge-air cooler) are standard equipment on most late-model turbocharged vehicles nowadays. The hot air discharged from the turbo is routed through a stack of tubes with internal fins. Heat is transferred from the pressurized air to the fins and then to the outside of the metal tubes. As outside ambient air flows over the intercooler the heat is transferred out of the tubes through external fins. The result is cooler air delivered to the engine. The intercooler used in this process is commonly referred to as an air-to-air heat exchanger. This setup is found in most diesel applications.

Water-To-Air Heat Exchanger

Some setups such as the 2011+ Ford 6.7L Powerstroke use water (or coolant) rather than air to cool the air discharged by the turbocharger. A pump circulates coolant thru the closed system from the radiator to the heat exchanger. While the coolant and air don’t actually make contact, the heat transfer is extremely efficient. There are a few other benefits to using a water-to-air setup. The intercooler cores are generally much smaller and less piping is required, which offers reduced turbo lag and getting the turbo to peak boost faster.

A setup like this is generally reserved for heavy-duty or race applications. These are also found on many performance vehicles from the factory. It does require additional accessories compared to air-to-air setups, advancing its complexity and the associated costs. This can also increase the possibility of a leak if not done properly.

The Benefits of Cold Air

As you may remember from science class, cold air is denser than warm air. Cold air features molecules that are packed together closer. When air is heated, the molecules start to move around faster. They become spaced further apart, so there is less oxygen. The number of oxygen molecules entering the combustion chamber per unit volume of air can be significantly greater with colder air. Cold air also helps to produce lower exhaust gas temperatures (EGT) when the same amount of fuel is delivered. It can also provide an increase in power levels at the same EGT, because of the ability to add more fuel.

Symptoms of Intercooler Failure

- Reduced Air Flow

- Turbocharger Failure

- A decrease in Engine Power

- Reduced Fuel Economy

- Smoke from the Exhaust

Common Causes of Failure

Intercoolers are extremely vulnerable to road debris and external damage that can cause premature failure. They are also susceptible to damage internally. A blocked hose, for example, can lead to abnormally high pressure that strains or possibly ruptures the intercooler.

Turbocharger failure can also cause the intercooler to sustain damage or become clogged. If you experience turbo failure it can be a good idea to replace the intercooler at the same time. Any particles or debris located in the old intercooler can enter the combustion chamber and cause damage to your engine.

Construction

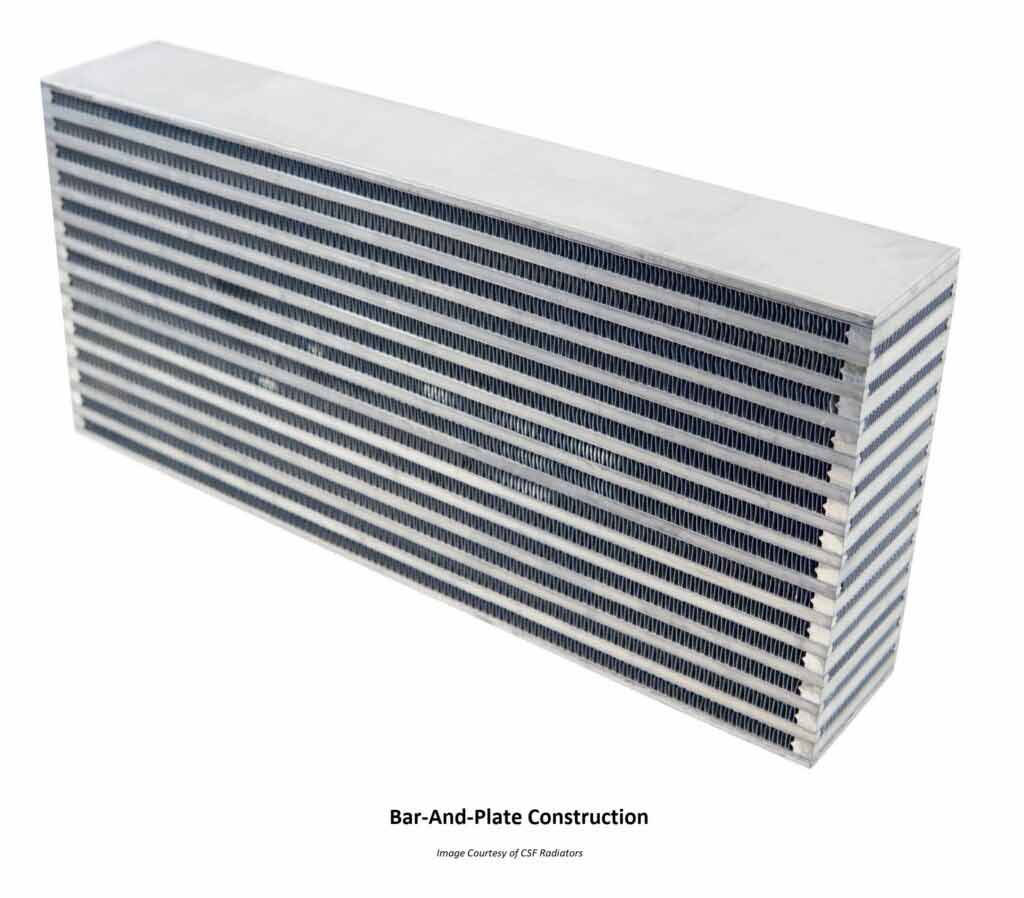

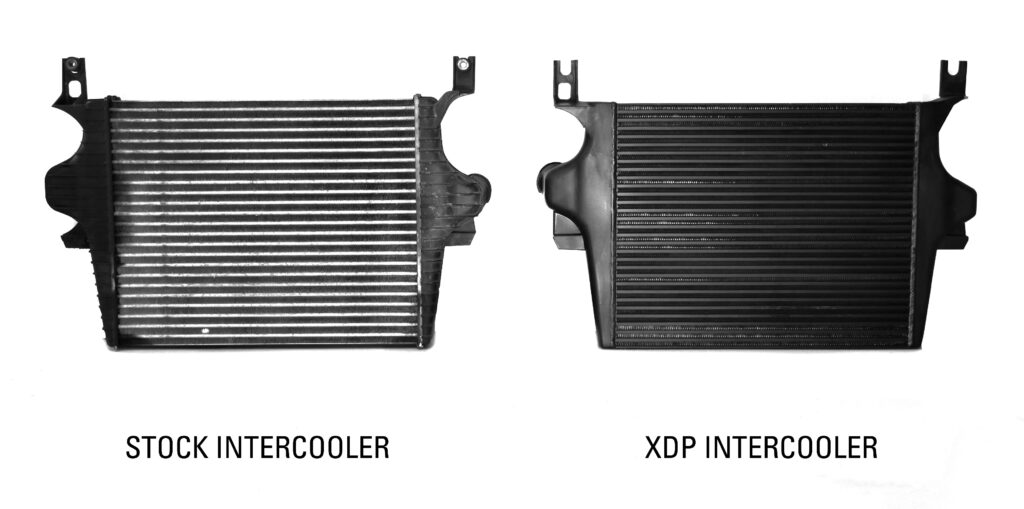

There are two main types of intercooler core designs: Tube-and-Fin and Bar-and-Plate. Tube-and-fin construction is typically what you will find on a stock/factory intercooler. Often times OEM manufacturers will use tube-and-fin simply due to the low production costs.

When you start shopping for aftermarket or performance intercoolers such as the XDP X-TRA Cool Direct-Fit HD Intercoolers you will notice many are upgraded with a more robust bar-and-plate construction. The inherent design of a bar-and-plate core helps to promote better heat transfer. It can operate better under high-heat conditions without losing efficiency. It is also better at handling high-boost applications than a similar tube-and-fin core.

Another benefit of bar-and-plate besides the improved cooling is an upgrade in strength and durability. The heavy-duty construction does add a little extra weight, but this significantly helps to withstand any potential damage from being mounted at the front of the vehicle. This additional strength also results in higher pressure tolerances and lower failure rates. The biggest drawback to bar-and-plate intercoolers is typically the higher costs to manufacture them.

Another technique used to strengthen intercoolers is upgrading from the stock plastic end tanks. Some intercoolers utilize 100% tig welded steel or cast aluminum end tanks. This lends itself to increased strength and is essential with higher boost pressures. Plastic end tanks are adequate for stock vehicles and failures are pretty minimal until a vehicle is modified. Plastic intercooler failures can become much more common especially on diesel trucks when the boost levels are increased.

Direct Fit

When shopping for an intercooler it is also a good idea to make sure it is a direct-fit (or direct bolt-in) for your application. Unlike a universal intercooler which can require custom brackets and some fabrication, direct fit means no major modifications are required in order for installation. Simply remove the factory unit and swap in the new intercooler while re-using all your stock brackets, mounting points, and plumbing components.