Whenever you add larger tires to your truck you will probably notice what feels like a significant loss of power behind the wheel. This decrease in performance is especially noticeable when towing, hauling a heavy load, or driving up a steep grade. The reason your truck is feeling a little sluggish now is because you have effectively changed the final drive ratio. Let’s dive in with Ring & Pinion 101 and discuss why it is necessary to upgrade the gears when you install a taller tire.

WHAT IS A GEAR RATIO?

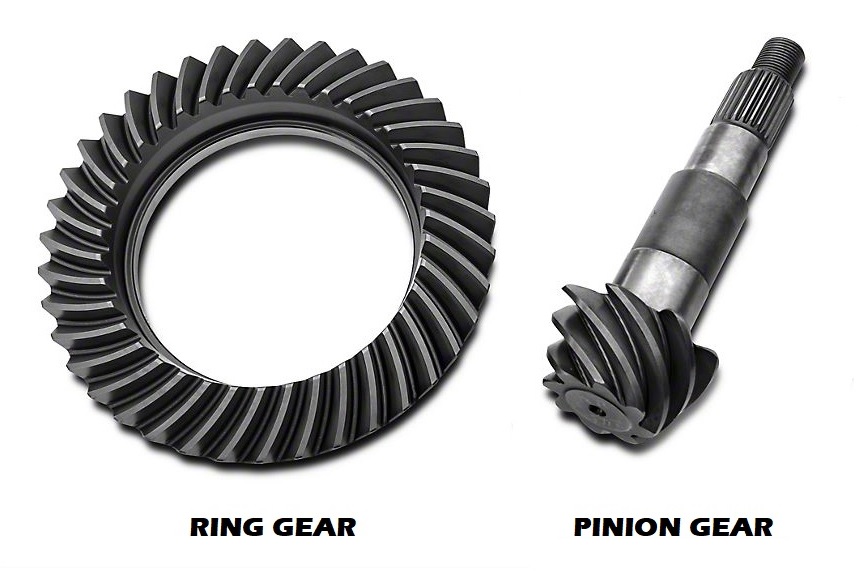

You have probably seen numbers such as 3.08, 3.73, or 4.10 before. These are the ratio of the ring-and-pinion gears in the rear axle. The numbers are more accurately written out as 3.08:1, 3.73:1, or 4.10:1. The ratio is the number of teeth on the ring gear divided by the number of teeth on the pinion gear. So, if the ring gear has 41 teeth and the pinion has 11 teeth, the ratio is 3.73:1 (41 divided by 11). For every one revolution of the ring gear, the pinion will turn 3.73 times.

SO WHY IS THIS NUMBER IMPORTANT?

Now for the confusing part, let’s temporarily throw everything you learned about math in elementary school out the window. Higher numerical gear ratios are referred to as a “lower gear” or “shorter gear”. Lower numerical gear ratios are called a “higher gear” or “taller gear”. For example, if you have 3.73’s and you replace them with 4.10’s you are installing a lower gear.

To calculate the torque multiplication provided by your axle gears you can simply multiply by the gear ratio. For example, let’s assume that the engine and transmission are delivering 100 lb-ft of torque to the pinion gear. If the gear ratio of the ring-and-pinion is 3.73:1, then the output torque is 373 lb-ft (100×3.73). Similarly, if the gear ratio is 3.08:1, then the output torque will be 308 lb-ft. It’s easy to see that the lower 3.73:1 gears put more power to the ground than the higher 3.08:1 gears. Keep in mind that the engine’s power has not changed, but that the available torque to the tires has.

To sum it up, lower gears result in more torque and quicker acceleration, higher gears offer better cruising and fuel economy.

AXLE GEARS vs. ENGINE RPM

Since lower gears provide greater torque multiplication, it would seem that they are always the ideal choice? The downside to a lower gear is that it requires more input speed (engine rpm) to produce the same output speed (tire rpm). Higher gears multiply torque less, but they require less input speed to deliver the same output speed.

If the transmission is in a gear with a 1:1 ratio and the rear gears are 3.08s, then the engine must turn 3.08 times for every one rotation of the tires. Lower 4.10 gears would make the engine turn 4.10 times for each turn of the tire. So a lower gear results in a higher engine rpm at any speed. Since a lower gear ratio will have your truck cruising at a higher rpm it will also result in a decrease in fuel economy and increase the wear and tear on your engine.

TO GEAR OR NOT TO GEAR, THAT IS THE QUESTION

Let’s say your truck came with a 32” tall tire and 3:73 gears from the factory. After a while, you might get the itch to start modifying it (like most of us) and give it a more aggressive stance. By installing that lift kit and upgrading to a 40” tire you are now running a tire that is 25% taller! Going from a 32″ tire to a 40″ tire might not sound like a big deal, but let’s look at another way. Pretend you still have that same truck with the stock 32” tall tire. Instead of changing out the tires, imagine you replace the factory 3.73 gears with a set of 2.80 gears (3.73 divided by 25% = 2.797).

So with a 40″ tire and stock 3.73 gears what gear ratio should you install? To compensate for a tire that is 25% taller, typically you will want to switch to a gear that is approx. 25% lower. If you multiply 3.73 x 1.25 it comes out to approx. 4.66. There is no 4.66 gear available in the aftermarket, so in theory, you could go with either a 4.56 or a 4.88. The 4.56 would be 2% higher than the stock 3.73, the 4.88 would be approx. 5% lower. When you take into consideration the additional weight of the larger tires the 4.88 would probably be a good all-around choice. Much of this will come down to personal preference of course, and how you use your truck on a daily basis. Some people may decide to go with a gear even lower than a 4.88.1.

CAN’T I JUST ADD MORE POWER

You’re probably wondering to yourself right about now, can’t I just add more power and call it a day? Adding horsepower can help if you are installing a tire that is just slightly taller than stock, but it won’t compensate for tires that are significantly larger. More power unfortunately doesn’t correct the final drive ratio like a ring and pinion swap. Bigger tires and incorrect gearing can also add additional stress to the transmission, decreasing its durability and longevity. Dollar for dollar, no performance part will make as big a difference in overall power and drivability as matching up the axle ring and pinion ratio to the new tire diameter.

SO I SIMPLY NEED TO REPLACE THE GEARS IN THE REAR AXLE?

If your truck is 2wd, then you only have one ring and pinion set to replace (the rear axle). If it is a 4wd then you need to upgrade the ring and pinion in BOTH the front and rear axle. Not replacing the front and rear gears (so they match), can damage the transfer case or other driveline components.

CORRECTING THE SPEEDOMETER

If your speedo is no longer reading correctly after your tire and/or gear swap there are a variety of programmers available that have the capability of updating this information. Simply use the programmer to set the new Tire Size and Gear Ratio and easily reprogram your truck’s ECM/PCM.

MATCHED SETS

It is strongly advised to run brand new “matched sets” only. Don’t try and save a few bucks and purchase used gears, or only changing the ring gear (or pinion gear). When the gears are manufactured they are subjected to a gear lapping process. Gear lapping is the process of imparting a very fine finish and a high degree of accuracy to the gear teeth. This process further refines the tooth surface and achieves the desired contact pattern.

COVER YOUR REAR

There is a wide assortment of differential covers available in the aftermarket for front and rear differentials which are a popular upgrade. The increased oil capacity and internal/external fins offer improved oil cooling. Another benefit is the die-cast aluminum construction helps to strengthen the differential (compared to a stock cover).

SOME ASSEMBLY REQUIRED

The installation of gears can be intimidating if you have never done it before. It also requires some specialty tools such as a dial indicator, bearing puller, bearing press, and gear marking compound. If this is something you have not done before (or aren’t comfortable learning on the job), you might want to search for a local shop to install the gears for you. Rates will vary depending on what part of the country you are in and shop labor rates.

WHAT PARTS DO I NEED?

High-quality gears are available from suppliers such as Yukon Gear and USA Standard Gear. When purchasing a set of gears don’t forget the master overhaul kit, this will give you all of the bearings, shims, gaskets, and bolts required for proper installation. Refer to your owner’s manual for the recommended gear oil weight and capacities. Finally, with positraction or a limited-slip differential, don’t forget the limited-slip additive or friction modifier. This simply gets added along with the gear oil when filling up the differential.

Shop at XDP.com and upgrade your Ford Super Duty, Chevy Silverado, GMC Sierra, or Dodge Ram today.