History/General Info

If you are familiar with diesel trucks, you have probably heard of the first-gen Dodge. When Dodge introduced the 5.9L 12-Valve ‘6BT’ engine it helped create a new standard for OEM diesel performance and completely revitalized their truck lineup. The Dodge AD platform originally debuted in 1972 and was used all the way up to 1993. Beginning in 1989, Dodge began to offer a 5.9L Inline 6 Cylinder Turbodiesel in their 3/4 and 1-ton Dodge pickups. The 5.9L diesel quickly became a popular alternative to Dodge’s V-8 gas engines, as the diesel offered nearly double the torque at low engine speeds. The 5.9L diesel had some unique features never seen on a diesel pickup truck before, including a turbocharger and direct fuel injection. It was revolutionary for the time and had a huge impact on drivability and towing capability.

Turbocharger

A turbocharger uses exhaust gas and converts this energy into compressed air. This condensed air is forced into the engine which helps translate into more power, improved fuel economy, and better towing performance, especially at higher altitudes. The turbodiesel engine vaulted Dodge’s aging D250/350 & W250/350 (Ram) platforms to a best-in-class torque rating of 400 lb-ft. General Motors & Ford were still utilizing naturally aspirated diesel engines with GM’s Detroit Diesel 6.2L offering 240 lb-ft of torque, while Ford’s International Harvester 7.3L IDI was rated at 338 lb-ft of torque.

Now 160 horsepower and 400 lb-ft of torque might not seem that impressive by today’s standards, especially when you compare it to many of the later-model diesel offerings. Fortunately, you can crank up the horsepower and torque numbers on the 6BT relatively easily. Aftermarket upgrades are available that drastically raise the factory ratings and really help wake it up. Best of all, since the 6BT was originally designed for commercial and agricultural applications, the robust design is more than capable of handling the bump in power without needing to completely tear it down.

1989-1991 Model Years

Like most full-size pickups Ram trucks were available in three series, which designate payload: 150-series (1/2-ton), 250-series (3/4-ton), and 350-series (1-ton). Two-wheel drive Rams got a “D” prefix, while four-wheel drive Rams were designated with a “W”.

The base engine in 1989 was a 3.9-liter V6, with optional 5.2L and 5.9-liter gas V8s available, but the big milestone was the arrival of the 5.9L diesel in the 3/4 and 1-ton trucks. The diesel engine was initially only available with a regular cab and a long bed. The club cab (extended cab) debuted with the diesel engine on the D250/W250 in 1990 and on the D350/W350 in 1992.

1991.5-1993 Model Upgrades

During the 1991 model year, the biggest highlight was when Dodge added an air-to-air intercooler to the diesel trucks. The hot compressed air that exited the turbocharger now traveled through an intercooler and was cooled down before entering the engine. A cooler and denser air charge helps to produce a more efficient combustion process and typically results in lower EGTs, improved fuel economy, and more power. Also in 1991, the automatic transmission was upgraded from the 3-speed A727 Torqueflite to the 4-speed A518 (46RH), which aided in improved fuel economy. These additions make the 1991.5-1993 model years slightly more desirable than 1989-1991 trucks for many buyers.

5.9L Killer Dowel Pin (KDP)

Although many consider the 12v 5.9L diesel engine to be one of the most reliable engines ever manufactured, it is not without its faults. One popular issue to be aware of is the Killer Dowel Pin or KDP. The term refers to a dowel pin failure inside any 1989-2002 12-valve or 24-valve 5.9L engine’s timing gear housing. This problem has the potential to “kill” an engine sometimes causing damage so severe that it cannot be repaired.

The 6BT features a steel pin that is pressed into the block and aligns the aluminum timing gear housing to the engine. It is positioned above the cam gear and next to the injection pump gear. From the factory, the pin is not secured and over time due to engine vibration and other factors, the dowel can become dislodged from its bore. If the pin comes out it can possibly work its way down without doing any harm or, if you are not so lucky, all sorts of damage can ensue.

There are plenty of kits available for this issue and are relatively inexpensive. The most common fix involves bolting on a teardrop-shaped steel retainer that secures the pin in its bore. This retainer prevents the pin from backing out and falling into the engine. Installing a KDP kit is cheap insurance.

What To Look For When Purchasing

Like any older pickup truck, rust can be common. This is even more prevalent if you live in an area that gets snow, where salt and brine solutions are used on the roads during the winter. Check the bottom sides of the bed, the cab corners, rocker panels, and the floor for metal that might need replacing. Water getting through the vent windows or worn-out weather-stripping can also lead to rust in the doors.

Trucks with higher mileage or hard miles will most likely need to have the suspension components gone thru. These trucks utilize kingpins that tend to wear out over time. The automatic transmissions were not particularly the stoutest and might need to be rebuilt or upgraded, especially if you have plans to raise the power levels of the 6BT. Finally, as in many older vehicles, electrical gremlins can be present or begin to appear over time.

Pros/Cons

Pros

- Classic Styling

- Simple & Reliable Engine

- Great Investment Potential

Cons

- Killer Dowel Pin

- Weak Automatic Transmissions

- Typical Rust Issues (Especially in the Snow Belt)

- Horsepower/Torque Levels are Inferior to Modern Trucks

Review

With the classic styling and the 5.9L diesel engine under the hood, the 1989-1993 Dodge trucks can be considered a modern-day classic with very good investment potential. Rust is probably the biggest consideration when shopping for a D250/350 or W250/350. Locating a solid rust-free truck from a dry arid climate like the southwest region of the US can be beneficial. This can save time and money having to perform extensive rust and metal repairs.

1989-1993 Dodge 5.9L Popular Aftermarket Upgrades

160 hp and 400 lb-ft of torque might have been impressive in 1989, but it pales to the power levels of a late-model diesel truck. Luckily the 6BT really responds well to modifications and it can help close the gap quite considerably. Whether you are looking for upgraded performance or more power for towing, these are some popular upgrades.

1. Fuel Pin & Governor Spring Kit

This new governor spring allows you to rev the 5.9L up to 3,200 RPM, from the factory 2,500 RPM. The additional 700 RPM really helps improve the drivability. A revised fuel pin increases the volume of fuel to the engine. This simple mod can net you up to 40 hp and 100 lb-ft of torque. These are two of the best bang-for-the-buck modifications you can do to wake up the 6BT.

2. Air Filter

An engine is basically a big air pump. The more air that flows in and out, the more power you will make. A less restrictive air filter helps your engine breathe better.

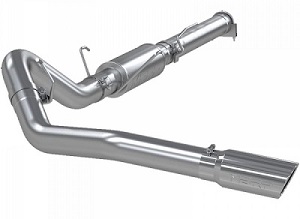

3. Exhaust

Mandrel bends and larger diameter piping will help free up some additional power in your rig. An exhaust system is always one of the most popular modifications in any vehicle (diesel or gas).

4. Fuel Injectors

Replacing worn fuel injectors will help restore power in your truck.

5. Lift Pump

A high-performance diesel engine demands higher fuel flows. The best way to do this and prevent air/vapor in the fuel system is with a quality Air/Fuel Separation System such as one from Air Dog or FASS.

6. Upgraded Turbocharger or Turbocharger Housing

An upgraded turbocharger or turbo housing can give you more boost, or simply help to reduce turbo lag.

7. Killer Dowel Pin Kit

As previously mentioned the (KDP) Killer Dowel Pin Kit is cheap insurance for your 5.9L engine.

1989-1993 Dodge 5.9L 12V Diesel Engine Specifications

| Production Years: | 1989, 1990, 1991, 1992, 1993 | |

| Model Availability: | D250, D350, W250, W350 | |

| Common Names: | 5.9, 5.9L, 6BT, 12V, 12 Valve, 1st Generation, 1st Gen | |

| Configuration: | Inline 6 cylinder | |

| Displacement: | 359 cubic inches, 5.9 liters | |

| Bore: | 4.02″ (102mm) | |

| Stroke: | 4.72″ (120mm) | |

| Cylinder Head: | Cast Iron | |

| Engine Block: | Cast Iron w/ 6 Head Bolts Per Cylinder | |

| Firing Order: | 1-5-3-6-2-4 | |

| Compression Ratio: | 17.0 : 1 | |

| Crankshaft: | Forged Steel, 7 Main Bearings | |

| Pistons: | Cast Aluminum | |

| Connecting Rods: | Forged-Steel, I-Beam | |

| Intake Manifold: | Cast Aluminum | |

| Injectors: | Bosch | |

| Injection: | Direct Injection (DI), Mechanical Injection Pump, Mechanical Fuel Injectors | |

| Fuel Pump: | Bosch VE44 Rotary Injection Pump | |

| Aspiration: | 1989 – 1991 | Holset H1C Turbocharger, Non-Intercooled |

| 1991.5 – 1993 | Holset H1C Turbocharger, Air-To-Air Intercooler | |

| Valvetrain: | OHV, 2 Valves Per Cylinder, Solid Lifter Camshaft | |

| Valve Lash (Clearance): | Exhaust Valve: | 0.020″ (Engine Cold) |

| Intake Valve: | 0.010″ (Engine Cold) | |

| Weight: | Approx. 1,100 lbs (Dry) | |

| Oil Capacity: | 12 qts w/ Filter (11.4L) | |

| Governed Speed: | 2,700 rpm | |

| Horsepower: | 160 @ 2,500 rpm | |

| Torque: | 400 @ 1,600 rpm | |

| Battery: | Group Size 34 | |

| Transmissions: | 1989-1993 | Getrag 360 5-Speed Manual |

| 1989-1991 | Torqueflite A727 3-Speed Automatic | |

| 1991.5-1993 | A518 (46RH) 4-Speed Automatic with Overdrive |

Fluid Specifications & Capacities

| Engine Oil: | 15W-40 | Ambient Temperature > 10° F | 12.0 Qts Capacity w/ Oil Filter (11.35L) |

| 10W-30 | Ambient Temperature 0 – 30° F w/o Block Heater, < 0° F W/ Block Heater | 12.0 Qts Capacity w/ Oil Filter (11.35L) | |

| 5W-30 | Ambient Temperature < 0° F w/o Block Heater | 12.0 Qts Capacity w/ Oil Filter (11.35L) | |

| Engine Coolant: | 50/50 Ethylene Glycol Coolant, Distilled Water | 24.0 – 26.0 qts Capacity (~6 gallons) | |

| Automatic Transmission Fluid: | Torqueflite A727 3-Speed | Dexron III or ATF+3 | 8-9 qts Service Refill Capacity 12-15 qts Dry Fill Capacity |

| Automatic Transmission Fluid: | A518 (46RH) 4-Speed | ATF+4 | 4.0 qts Service Refill Capacity 14.5 – 16.5 qts Dry Fill Capacity |

| Manual Transmission Fluid: | Getrag G360 | 5W-30 Motor Oil | 3.5 qts |

| Transfer Case Fluid: | NV231/NV231HD | ATF+4 | 1.25 qts |

| NV241 | ATF+4 | 2.4 qts | |

| NV241HD | ATF+4 | 3.25 qts | |

| Front Differential Fluid: | Dana 60 | SAE 75W-140 | 3.15 qts |

| Rear Differential Fluid: | Dana 70 2WD | SAE 75W-140 | 3.5 qts |

| Dana 70 4WD | SAE 75W-140 | 3.9 qts | |

| Dana 80 2WD | SAE 75W-140 | 3.2 qts | |

| Dana 80 4WD | SAE 75W-140 | 4.8 qts |

Maintenance Schedule

| Service Procedure | Interval |

| Replace Engine Oil & Filter: | 6,000 miles/6 months under normal driving conditions 3,000 miles/3 months under severe driving conditions |

| Replace Fuel Filter: | 12,000 miles/12 months under normal driving conditions 6,000 miles/6 months under severe driving conditions |

| Replace Air Filter: | 24,000 miles/24 months |

| Engine Cooling System: | 24,000 miles/24 months |

| Check/Adjust Valve Lash: | 24,000 miles/24 months |

| Adjust Automatic Transmission Bands: | 24,000 miles/24 months |

| Replace Automatic Transmission Fluid & Filter: | 30,000 miles |

| Replace Manual Transmission Fluid: | 60,000 miles |

| Replace Transfer Case Fluid: | 120,000 miles |

Disclaimer: XDP is in no way affiliated with Cummins or any of its subsidiaries or related companies, and that Cummins has not authorized the sale of any of XDP’s parts, and has not tested or approved any of XDP’s parts for use in genuine Cummins brand products.