History/General Info

In 2003, the third generation of diesel-powered Dodge trucks was introduced. The new Ram 2500/3500 received some major upgrades including new drive-line components, a common-rail fuel injection setup, as well as interior and exterior updates. Dodge continued to incorporate the same recognizable semi-truck styling on the new 3rd gen trucks but made some updates to the grille and headlights for a slightly refreshed and updated look. The interior was also completely revised and featured a host of changes including an all-new dashboard. As the sales battle between manufacturers continued, Dodge also made some major changes to the 5.9L Diesel engine.

2003-2004 Dodge 5.9L Diesel

The 24-valve 5.9L Diesel switched from the VP44 injection pump to an electronically controlled common-rail fuel system. This provided more accurate fueling along with improved overall performance and reliability. Upgrading to a common-rail fuel injection system was also key to significantly boosting the horsepower and torque.

The common-rail system utilized a lift pump to send fuel to the Bosch CP3 Injection Pump. The pressurized fuel was then sent to the “common” fuel rail and distributed to electronic injectors. Bosch solenoid-activated electronic fuel injectors were controlled by the ECM to produce 2 injection events per stroke. These new injectors featured 8-hole nozzles that sprayed at a 143-degree angle.[1]

In addition, the engine block was now cast in a stronger gray iron, with reinforced rails and a stiffener plate to handle the increased power.[2] The engine also retained the same cast-aluminum pistons and forged-steel connecting rods as the prior generation.

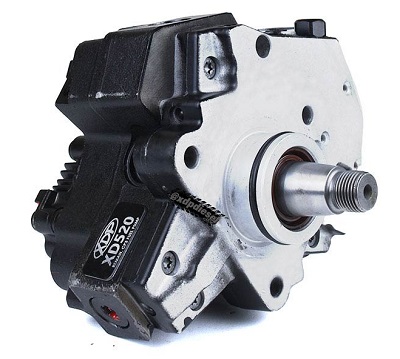

Bosch CP3 Fuel Injection Pump

The Bosch CP3 Fuel Pump is a radial-piston pump comprised of three cam-driven plungers, a high-pressure and low-pressure circuit, a hardened-steel housing and a fuel pressure regulator, also known as a Fuel Control Actuator (FCA) or Magnetic Proportional Valve (MPROP). The CP3 pump’s primary responsibility was to produce high pressure fuel for the fuel injectors. In addition, the CP3 wasn’t directly involved with controlling injection timing or fuel volume. While it was still driven via the front gear train (1:1 with the crankshaft), the CP3 wasn’t timed to either the crankshaft or camshaft. This was a big change from the VP44 fuel pump found on the 1998.5-2002 engines which was also responsible for pressurizing the fuel, controlling the injection timing, and monitoring fuel flow.

Holset HE341CW Turbocharger

For 2003 and 2004, the 5.9L diesel utilized a Holset HE341CW Turbo (this replaced the Holset HY35W). The HE341CW is a fixed geometry turbocharger, that featured journal bearings with a seven-blade compressor wheel. This turbo also utilized a mechanical internal wastegate to avoid excessive drive pressure and overspeeding.

Horsepower/Torque

In 2003 the Standard Output (S.O.) 5.9L Diesel was rated at 235 hp and 460 lb-ft of torque. The 5.9L High Output (H.O.) Diesel broke the 300 hp barrier for the first time and was now rated at 305 hp and 555 lb-ft of torque. In 2004, the 235 hp engine was reserved only for models sold in California, with the S.O. models now matching the output levels of the 2003 H.O. engine.

Transmissions

Transmission choices included the standard NV4500 5-speed manual transmission and an optional 48RE 4-speed automatic transmission with overdrive. A NV5600 6-speed manual transmission was also offered, exclusively with the H.O. Diesel engine. Like many of the other early generations of diesel-powered trucks, the automatic transmission was typically not capable of handling significant increases in power.

Chassis & Drivetrain

Another big upgrade was a new hydroformed frame with boxed sections. This new frame design helped increase the overall rigidity and contributed to improved steering and handling. In addition, the upgraded frame allowed the new heavy-duty pickups to claim a segment-leading Gross Vehicle Weight Rating (GVWR) of 12,000 pounds.[3] The Dodge Ram Heavy-Duty pickups featured standard four-wheel disc anti-lock brakes with the largest rotors in the segment. With giant 13.9″ (353mm) front and rear rotors, they were significantly larger than the outgoing 2002 model. These new brakes required a move to larger 17-inch wheels, but significantly helped increase the braking power.

To further increase driveline durability, new front and rear differentials were introduced. These differentials were supplied by American Axle & Manufacturing (AAM) and were similar to those found in GM trucks but are typically not interchangeable due to differences in the axle tubes, hubs, and brake/suspension mounting bracketry. Ram trucks utilized two transfer cases, a conventional manual shift (NV271D) and an electric shift (NV273D). The manual transfer case was standard on ST and SLT 4WD models, while the Laramie featured electronic shifting controls.

What to Look for When Purchasing

The 5.9L Diesel is a highly regarded motor and deserves all the praise it receives, but internal engine issues can arise from time to time. Make sure to inspect the vehicle closely before purchasing. Take it for a lengthy drive and get it up to operating temperature. During the test drive pay close attention to the engine and transmission. Make sure the transmission shifts properly and listen for any noises. Furthermore, check for crankcase blow-by; with the engine idling simply take the engine oil cap off and check for excessive fumes. Next, place the cap upside on top of the oil fill opening. The crankcase pressure should not blow it off. If the pressure is too high the oil fill cap will typically blow off. If this is the case, you might want to consider the cost of an engine rebuild when making an offer.

The common-rail fuel injection system on these trucks can begin to develop issues before the 200K mile mark. If these haven’t been touched in a while, make sure to budget enough money for possible replacement of the injectors or CP3 pump. The lift pump was barely adequate for a stock truck and there is a chance that the CP3 could have been run without proper lubrication (fuel). The front-end suspension and steering components are also prone to wear and tear. Tie rods, ball joints, bushings, as well as the track bar are items that can be commonly worn out and require replacement.

Rust

As with any older pickup truck rust can be a common issue (depending on your geographic location). Check the rockers, cab corners, bedsides, and wheel well openings for rust or signs of prior rust repair. Inspect for body filler or recent paintwork. Body filler applied directly on rust areas is one way to hide problem areas. This is not an adequate or proper way to repair rust and will not last very long. The frame can also develop varying levels of rust. Closely inspect the frame, particularly where the frame sections are welded together.

Pros/Cons

Pros

- Larger Brakes

- Updated Interior

- New Hydroformed Frame

- Common Rail Fuel Injection

Cons

- Common Rust Issues

- Paint/Clearcoat Problems

- Worn Front Ends (Steering Components)

- Relatively Weak Automatic Transmission

2003-2004 Dodge Ram 5.9L Popular Aftermarket Upgrades

The 5.9L 24-Valve is relatively simple to work on and overall was a very reliable engine. The following is a list of some of the most popular aftermarket upgrades. Shop for your 2003-2004 Dodge Ram 5.9L Diesel at XDP today!

1. Air Intake System

An Air Intake System (or Cold Air Kit as they are often referred) is always a popular upgrade and are also typically amongst the first upgrades done by most diesel owners.

Find one for your truck: Air Intake System

2. Tuner/Programmer

This one is also a no-brainer and is often one of the first modifications someone typically does to their diesel. They are available with a wide range of features and some also let you monitor the vitals. Probably the easiest way to add some additional power to your truck.

Search the wide selection of choices: Tuners/Programmers

3. Lift Pump

Lifts pumps, transfer pumps, or fuel pump are common failure items on these trucks. It’s a good idea to upgrade your fuel lift pump as the factory one can barely keep up at factory levels. Something like an AirDog or FASS is a good idea because they provide additional volume to keep your system operating properly.

Upgrade your fuel system: Lift Pumps

4. Steering Components

On a truck that is now pushing 20+ years old, if the majority of steering components haven’t been replaced at least once already, it is probably overdue. Parts such as Tie-Rod Ends, Drag Links, Pitman Arm, and Steering Dampers are available individually or as a convenient steering linkage assembly.

Find everything you need to restore your steering: Steering Components

5. Fuel Injectors

Direct-fit replacement fuel injectors are available to help save you time when the fuel injectors in your truck wear out and need replacement.

Shop for all your injector needs: Fuel Injectors

6. Intake Manifold

An aftermarket intake manifold is designed to enlarge the inlet area and optimize air distribution in the cylinder head for increased performance.

Replace your restrictive stock manifold: Intake Manifolds

7. Electrical System

Back in 2003, a 136 AMP alternator might have been adequate. Higher output alternators are a worthwhile investment for anyone auxiliary items such as a snow plow, on-board air systems, off-road lights, or an upgraded stereo system. In addition, components such as battery cables can wear or get damaged over time. Inspect the cables and replace them if necessary before they leave you stranded.

Find everything to upgrade your electrical system: Electrical System

8. Upgraded Clutch

For maximum holding power, especially in modified trucks with increased power levels, an upgraded clutch can be a necessity.

Upgrade your clutch: Clutches

9. Turbochargers

Replace the worn turbocharger in your truck with a stock replacement or an upgraded unit for better performance. Drop-in units like the Fleece Cheetah Turbocharger can also help improve throttle response and offer more top end power.

Shop for turbo’s: Turbochargers

2003-2004 Dodge Ram 5.9L Diesel Engine Specifications

| Production Years: | 2003, 2004 | |

| Common Names: | ISB 24V or 24 Valve 3rd Generation, 3rd Gen | |

| Configuration: | Inline 6 cylinder | |

| Displacement: | 359 cubic inches, 5.9 liters | |

| Engine Code: | 6 = 5.9L 6 cyl. Turbo Diesel C = 5.9L 6 cyl. Turbo Diesel (High Output) | |

| Bore: | 4.02″ (102mm) | |

| Stroke: | 4.72″ (120mm) | |

| Cylinder Head: | Cast Iron | |

| Engine Block: | Cast Iron w/ 6 Head Bolts Per Cylinder | |

| Firing Order: | 1-5-3-6-2-4 | |

| Compression Ratio: | 17.2 : 1 | |

| Crankshaft: | Forged Steel, 7 Main Bearings | |

| Pistons: | Cast Aluminum | |

| Connecting Rods: | Forged-Steel, I-Beam | |

| Intake Manifold: | Cast Aluminum | |

| Injectors: | Bosch | |

| Injection: | Direct Injection (DI) | |

| Fuel Pump: | Bosch High-Pressure Common Rail, Bosch CP3 Injection Pump | |

| Turbocharger: | 2003-2004 | Holset HE341CW Turbocharger, Air-To-Air Intercooler |

| Valvetrain: | OHV, 4 Valves Per Cylinder, Solid Lifter Camshaft | |

| Valve Lash (Clearance): | Exhaust Valve: | 0.020″ (Engine Cold) |

| | Intake Valve: | 0.010″ (Engine Cold) |

| Weight: | Approx. 1,150 lbs (Dry) | |

| Oil Capacity: | 12 qts w/ Filter (11.4L) | |

| Governed Speed: | 3,200 rpm | |

| Horsepower: | 2003 | 235 hp @ 2,700 RPM (Std) 305 hp @ 2,900 RPM (H.O.) |

| 2004 | 235 hp @ 2,700 RPM (CA) 305 hp @ 2,900 RPM (Std) | |

| Torque: | 2003 | 460 lb-ft @ 1,400 RPM (Std) 555 lb-ft @ 1,400 RPM (H.O.) |

| 2004 | 460 lb-ft @ 1,400 RPM (CA) 555 lb-ft @ 1,400 RPM (Std) | |

| Battery: | Group Size 27 | |

| Transmissions: | 2003 | NV4500 5-Speed Manual |

| 2003 | 47RE 4-Speed Automatic | |

| 2003-2004 | 48RE 4-Speed Automatic | |

| 2003 (H.O.) & 2004 | NV5600 6-Speed Manual |

Fluid Specifications & Capacities

| Engine Oil: | 15W-40 | Ambient Temperature > 10° F | 12.0 Qts Capacity w/ Oil Filter (11.35L) |

| | 10W-30 | Ambient Temperature 0 – 30° F w/o Block Heater, < 0° F | 12.0 Qts Capacity w/ Oil Filter (11.35L) |

| | 5W-30 | Ambient Temperature < 0° F w/ Block Heater | 12.0 Qts Capacity w/ Oil Filter (11.35L) |

| Engine Coolant: | 50/50 Mixture – Mopar 5 year/100,000 mile, Distilled Water | Approx. 7 Gallon Capacity | |

| Automatic Transmission Fluid: | 48RE 4-Speed | ATF+4 | 4.0 qts Service Refill Capacity 14.5 – 16.5 qts Dry Fill Capacity |

| Manual Transmission Fluid: | NV4500 5-Speed | SAE 75W-90 | 4.0 qts (8 pts) |

| NV5600 6-Speed (H.O.) | Mopar Manual Transmission Fluid | 4.75 qts (9 pts) | |

| Transfer Case Fluid: | NV271D | ATF+4 | 2 qts |

| NV273D | ATF+4 | 2 qts | |

| Front Differential Fluid: | 9.25″ AAM | SAE 75W-90 GL-5 | 2.45 qts |

| Rear Differential Fluid: | 10.5″ AAM | SAE 75W-90 or 75W-140* GL-5 | 2.65 qts |

| 11.5″ AAM | SAE 75W-90 or 75W-140* GL-5 | 3.8 qts | |

| Brake Fluid: | DOT 3 and SAE J1703 should be used. If DOT 3 brake fluid is not available, then DOT 4 is acceptable. | ||

| Power Steering: | Mopar ATF+4, Automatic Transmission Fluid |

*Recommended by Manufacturer when Towing

Maintenance Schedule

| Service Procedure | Interval |

| Replace Engine Oil & Filter: | 6,000 miles/6 months (under normal driving conditions) 3,000 miles/3 months (under severe driving conditions) |

| Replace Fuel Filter: | 12,000 miles/12 months (under normal driving conditions) 6,000 miles/6 months (under severe driving conditions) |

| Replace Air Filter: | 24,000 miles/24 months |

| Engine Cooling System: | 52,500 miles/36 months and then every 24,000 miles/24 months |

| Check/Adjust Valve Lash: | 24,000 miles/24 months |

| Replace Automatic Transmission Fluid & Filter: | 30,000 miles |

| Adjust Automatic Transmission Bands: | 24,000 miles/24 months |

| Replace Manual Transmission Fluid: | 60,000 miles |

| Replace Transfer Case Fluid: | 60,000 miles/48 months (under normal driving conditions) 30,000 miles/24 months (under severe driving conditions) |

References:

- https://www.dieselworldmag.com/diesel-technology/part-3-650-700hp-5-9l-common-rail-recipes

- https://www.drivingline.com/articles/cummins-history-lesson-4-03-07-59l

- https://www.allpar.com/d3/model/ram/ram-heavy-duty.html

Disclaimer: XDP is in no way affiliated with Cummins or any of its subsidiaries or related companies, and that Cummins has not authorized the sale of any of XDP’s parts, and has not tested or approved any of XDP’s parts for use in genuine Cummins brand products.