Whether you’re towing, commuting, or headed off-road, keeping your front-end in check is crucial for your truck. With so many vital steering and suspension components, checking on these front-end suspension parts is a good idea while doing routine oil changes.

How do you know when it’s time for a Front End Refresh?

Maybe you’ve noticed some uneven tire wear, excessive play in the steering wheel, creaking, or clunking sounds in the front end. These can all be signs that it’s time for some fresh suspension parts. Allowing suspension issues to persist can lead to premature wear on your steering, tires, braking system, and more. In some cases, vehicles that are neglected can become unsafe to drive.

Tie rods can fail or snap, wheel bearings deteriorate, and make unmistakable screeching sounds. As well as, ball joints becoming loose, causing further issues with steering and suspension components. Mileage can be the most significant factor when deciding when to replace components. For example, a vehicle with 150k miles is much more likely to need suspension parts than a lower mileage model.

Diagnosing Steering and Suspension

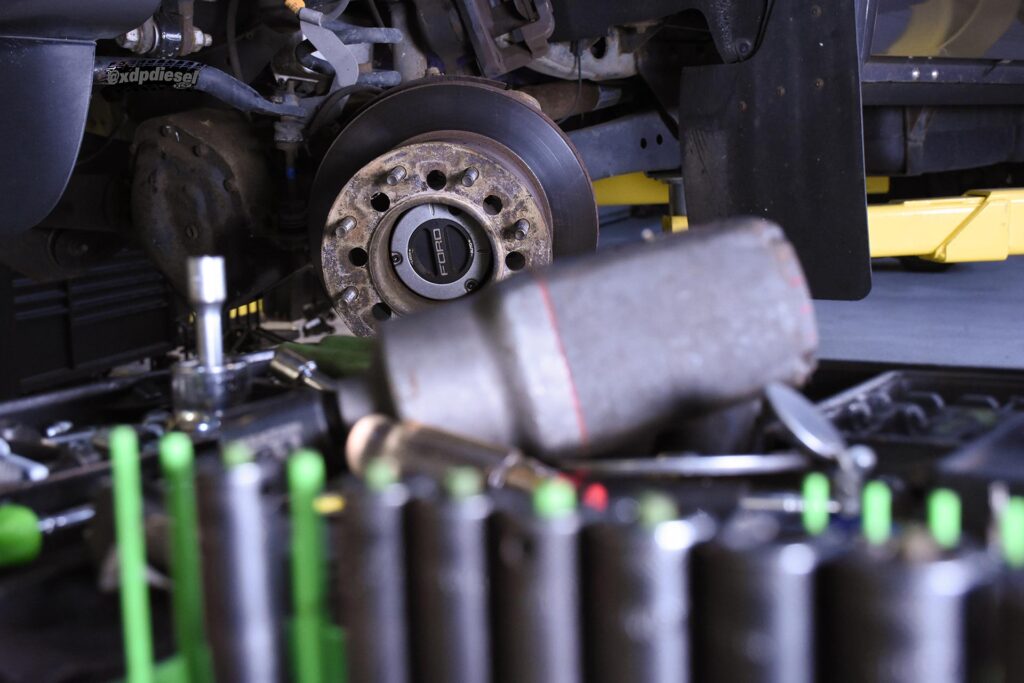

When doing front-end work on your vehicle, it’s important to go through diagnostic steps. This will give you the best idea of what to replace. Diagnosing a vehicle can be done by jacking up the front of the vehicle and checking the wheel for play by hand. Abnormal movement, clicking, rubbing, or clunking sounds could indicate your vehicle’s front end may be experiencing an issue. When looking at your front-end components, be sure to inspect dust boots, tie rod adjusting sleeves, and axle seals. Visually inspect components for wear or damage.

What should you replace?

Overall it’s never a bad idea to go above and beyond while you have things apart. This type of preventative maintenance can help prevent issues in the future. Ultimately, keeping you from getting stranded on the side of the road.

Swapping out the worn components such as ball joints, wheel bearings, idler arm, pitman arm, tie rod ends and sleeves, sway bar bushings and end links is a good idea. While not considered steering or suspension components, this can be a good opportunity to inspect the brake pads and rotors.

Reusing Front End Components

You can evaluate all the components and inspect parts to be potentially reused. This may vary based on the individual vehicle, as well as a number of contributing factors that may have affected the health of the front end. If you do find yourself reusing components, it’s always best practice to thoroughly inspect and clean components before reusing them, removing rust and road debris. Cleaning mating surfaces is crucial and if overlooked can cause issues when installing and maintaining front-end components.

Prepping New Parts for Install

Make sure you have what you need before beginning working on your vehicle’s front-end components. Staying organized when taking on projects that have so many parts and can have varying processes can be a big timesaver and make the job easier. Be sure to make a checklist that can keep you on track. This is extremely useful when making the list of parts you need to order, based on the components you will be replacing. Keep in mind that some kits come with everything you need, whereas some kits may need to be pieced together.

With a wire wheel, we were able to get these components back in working order.

Once you have all the parts you need, make sure to take this one important precautionary step. When installing new parts, especially tie-rods and movable components, anti-seize should be applied. Using anti-seize or a similar product, especially on threaded components such as tie rods, can be beneficial. This added precaution can keep parts from seizing together, in a similar way to a lubricant. This can be helpful the next time you go to remove bolts and replace front-end parts again in the future.

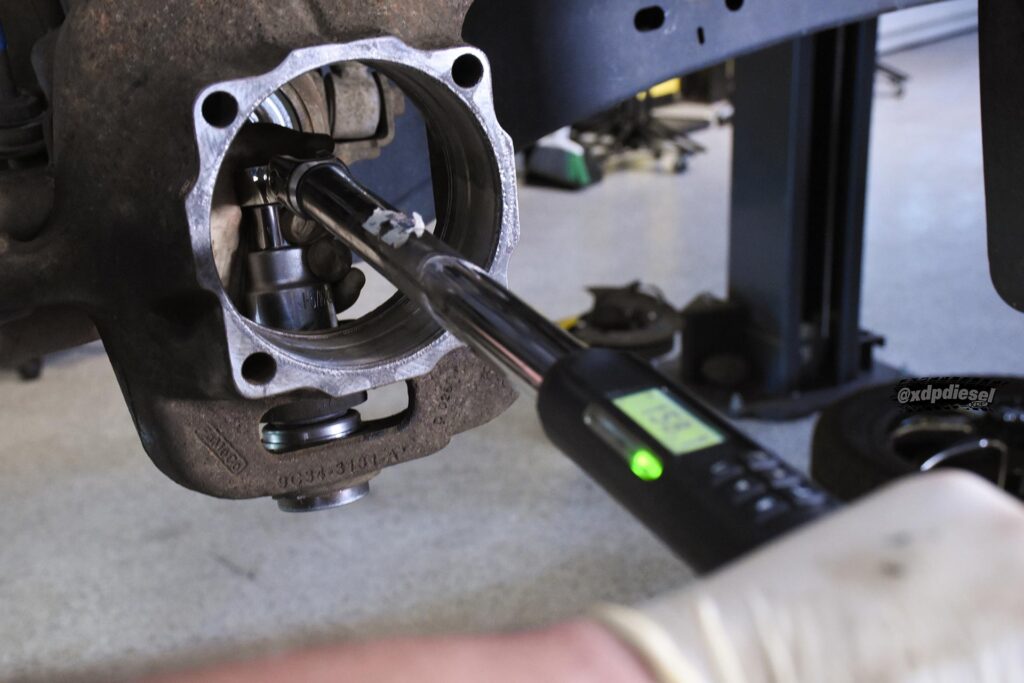

What is Torque Spec?

Making sure your new front-end components stay in place is just as important as replacing the worn-out parts in the first place. How can you achieve this? By ensuring all the necessary bolts that will be holding your new suspension components are properly torqued.

Torque spec is the required foot lbs. of force the manufacturer recommends in order to keep nuts and bolts securely in place. Whether it be lug nuts, tie rod ends, ball joints, traction arms, or other front-end suspension components, making sure hardware is torqued to spec is critical to ensure safety and continued use of your vehicle.

Seals

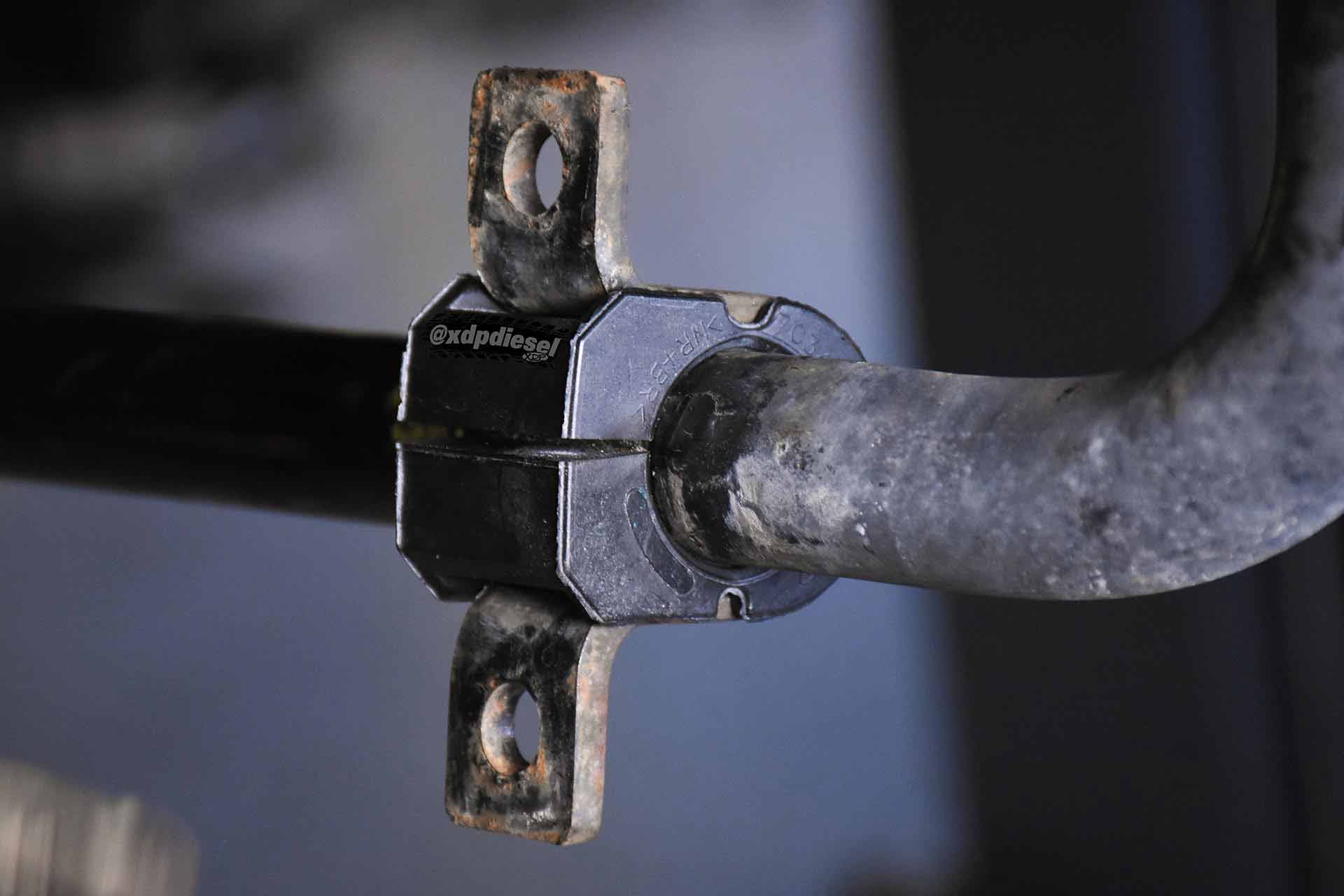

While replacing your front-end components, it can also be beneficial to replace seals that may be needed. When refreshing your suspension, it’s good practice to replace both vacuum and axle seals (where equipped). These seals help protect moving components from dust and debris, and ensure parts can move and flex properly. Keeping your vehicle’s front end driving smoothly.

When removing old seals that are damaged or broken, be sure to remove any debris in the area if present. In doing so, you create a clean space for your new seal to be installed. This also avoids potential damage to the newly replaced seal.

If you’ve been hearing strange noises coming from your front end or notice your truck tracking off center, it might be time to check in on your components. Visit XDP.com to get all of the parts you need to keep your truck on the road running longer!