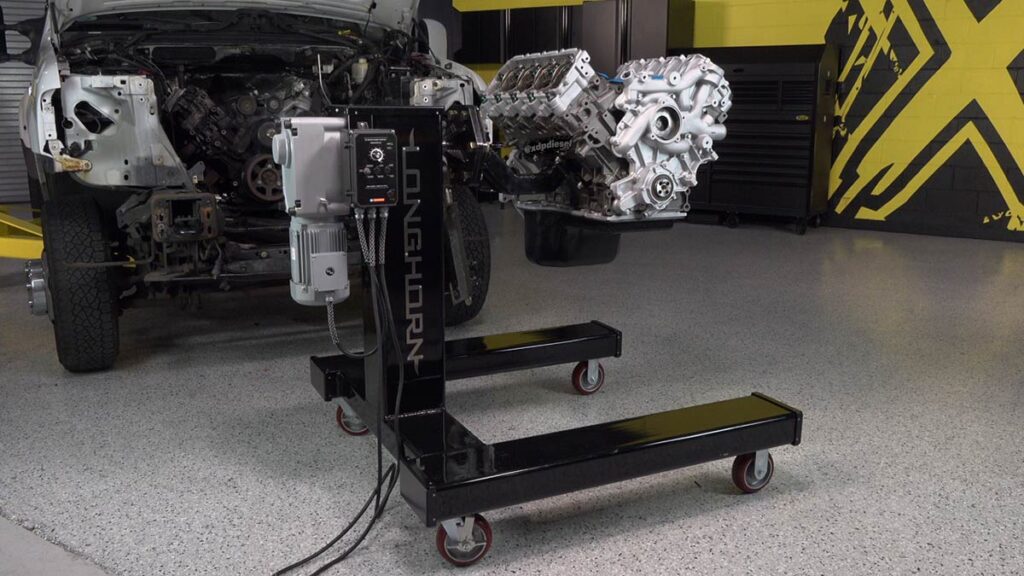

Professional shops require nothing less than professional grade equipment. The Longhorn Fab Pro Grade Rotating Engine Stand is what your shop needs to meet the demands of any engine build. Expertly manufactured with diesel engines in mind, this stand is designed to exceed the demands of your engine building department.[1] With the features and durability you need, the Longhorn Fab engine stand offers dependability, efficiency, and ease throughout your engine build.

The Benefits of an Engine Stand

An engine stand might seem like a humble piece of equipment, but its benefits for a shop are substantial. An engine stand provides easier access to both the bottom and top end of the engine during a rebuild. It offers this convenience by allowing the engine to be easily rotated and positioned by a single tech for rebuild. This hands-free positioning reduces mistakes, saves time, and increases productivity and profit.[2] Plus, using an engine stand can also help reduce strain on a technician’s body.

Finally, this ultra-heavy-duty essential shop tool is capable of holding diesel engines of varying sizes and weights. Overall, investing in an engine stand isn’t just about convenience. It’s about efficiency and the preservation of both the engine and the people who work on them.

While the dedicated engine shop is the largest market for a heavy-duty diesel engine stand, others can benefit from having one as well. From the DIY enthusiast, to race teams, and everyone in-between. This engine stand is a welcome addition in the shop for anyone that is building engines.

The Longhorn Fab Shop Pro-Grade Rotating Engine Stand

Longhorn Fab Shop first started manufacturing engine stands in 2017. They discovered there was nothing on the market that was built to meet their expectations and demands. Per Manfred Schreyer, the owner of Longhorn Fab Shop, “We’re known for manufacturing heavy-duty parts that are built to last and built in the USA and there wasn’t anything in the engine stand market that was living up to how we would build it or how we would abuse it, and they definitely were not made in America.”

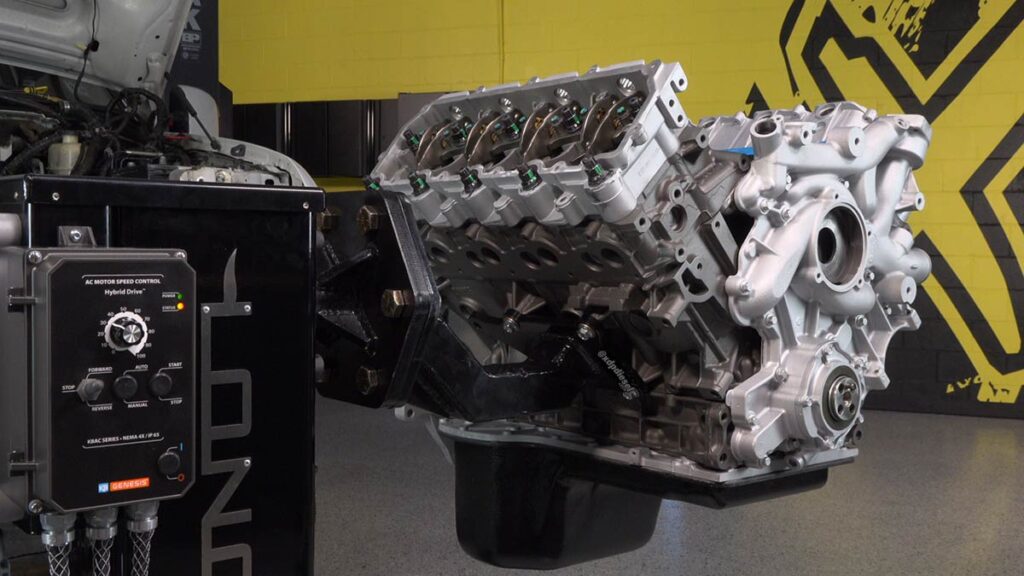

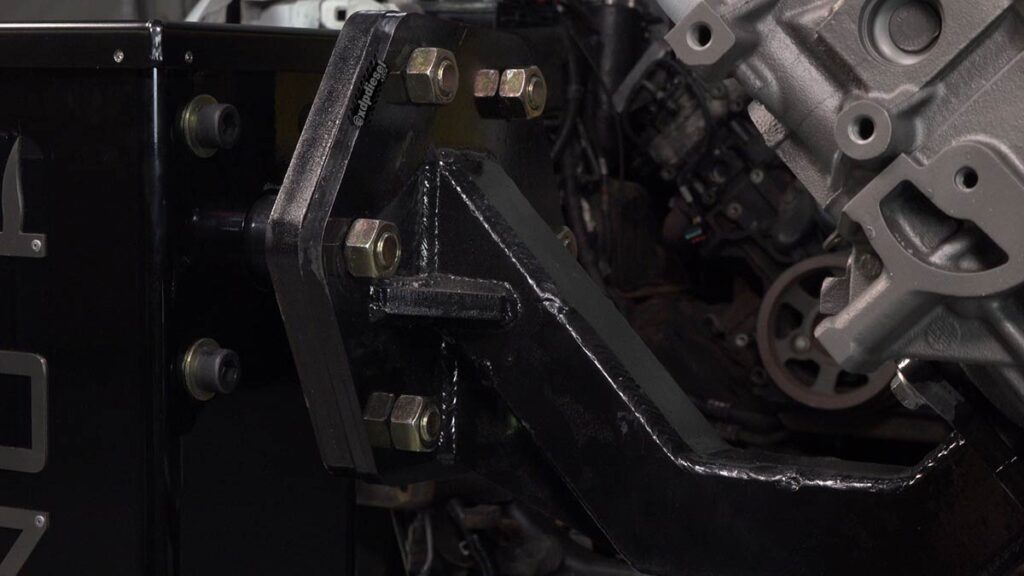

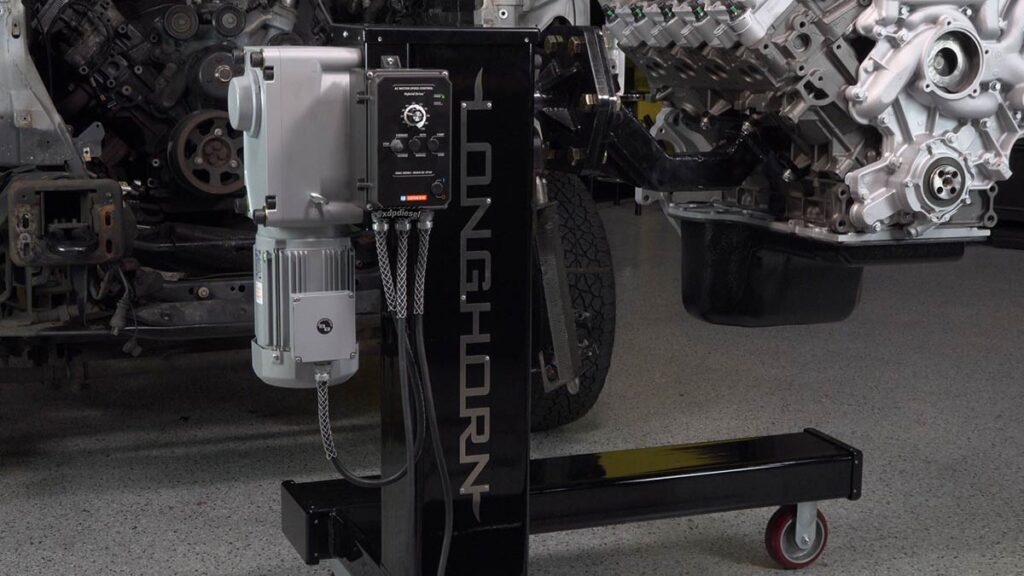

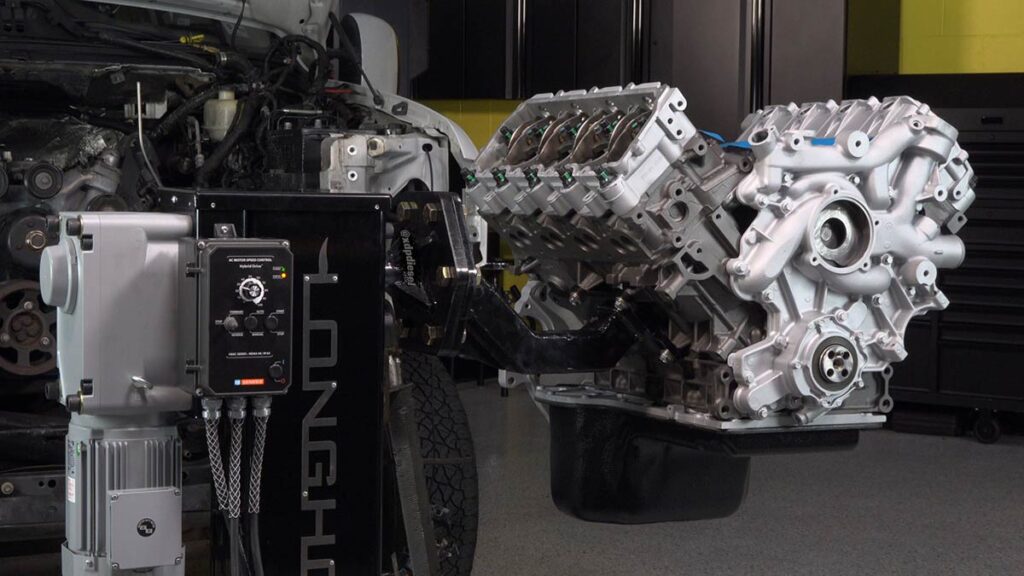

The Longhorn Fab Shop Pro-Grade Rotating Engine Stand offers an ultra-heavy-duty design capable of tackling any challenge. Specifically crafted with durability and reliability in mind, Longhorn Fab Shop provides specially made engine adapters, ensuring seamless compatibility. Additionally, the 1HP motor and industrial gear reduction drive grants full 360-degree access during engine assembly. The engine rotates on a 2” machine shaft and two 6,500-pound bearings.[3]

Key Features

For full 360-degree access, this engine stand is electrically gear driven. Rotation is easily controlled by the provided foot pedal. In addition, the four 1,200-pound casters allow you to easily roll the stand around the shop.

With hands-free adjustability and a built-in variable-speed industrial motor, it allows for easy engine movement along with reversing directions. These features amplify productivity and profits while reducing errors and time consumption.

The design, machining, welding, and assembling of the engine stand is all done in-house at Longhorn Fab. The casters, controls, and motor gearbox assemblies are all sourced, engineered, and assembled in the USA as well. The gearbox and controls package come with a 5-year warranty and lifetime warranty on the structure of the stand. Per Manfred, “We can offer that because we know the abuse we have put these through in testing and the industrial parts that go into them. For example, the variable frequency drive control plugs into a regular 110v wall outlet. It then converts that to 240v 3 phase and that powers the industrial motor attached to the gearbox. Each customer gets the benefit of a heavy-duty industrial motor, but the ease of being able to plug it into a regular wall outlet.”

How Longhorn Fab Engine Stands Will Help Complete your Engine Build

With engine building comes several common issues that shop techs face. The first of which is rear covers. Rear covers can crack and trying to replace one while the engine is sitting on a tire is unsafe. It is also not very ergonomical. Per Manfred, “That is why we offer a side mount option for our stands, remove a motor mount, bolt our mount on and then attach it to the engine stand. You can tear down and build up an entire engine without ever taking it off until it is a bare block that needs prepped.”

Another issue is the high torque and multistage process of torquing head bolts and mains. Conventional stands are typically harder to rotate. Many techs leave the engine in the upright position or upside-down position to torque it. This can put a lot of strain on the shoulders. Per Manfred, “Our engine stands rotate so effortlessly that many builders will turn the engine 90 degrees so they can push down on the torque wrench and use their body weight. Most engine stands on the market today barely hold a dressed motor, let alone someone pushing down on it to torque heads and mains.”

Finally, Longhorn Fab Shop Engine Stands are designed for efficiency and comfort in the working environment. They will ensure that the engine builder is taking care of and preserving their body for years to come. As Manfred explains, “It is the same reason they don’t use tire irons to change tires, they use an impact. It is faster, more ergonomic, and not demoralizing to know you have 32 lug nuts on a truck to take off and put on by hand. Same thing goes for engine stands.”

More about Longhorn Engine Stands

Longhorn Fab Shop additionally offers a variety of Engine Stands with versatile options like fork pockets, casters, or a floor mount pedestal stand. The caster version is the most popular, as you can hang a fully dressed engine off of it and roll it across the shop with one person very easily. The Fork Pocket Version is for shops that want it somewhat stationary or mount engines and move them with forklifts. The Bolt Down Version takes up the least amount of space, you can easily take the engine mount off of it, and it is completely out of the way.

Longhorn Fab Shops Professional Grade Engine Stands are rated for up to 2,000 lbs., with a center of gravity of 24” from the neck of the engine stand. Each stand is tested to get a rating of what it will hold and still function as expected, rather than what it will hold and pass the test. To get some insight, Manfred added, “We once bolted a fully dressed engine on one, strapped the stand in a trailer, and hauled it like that from Ohio to Idaho. It was a great test of long-term vibration, bouncing, and fatigue failure! It made it there and back with no issues or signs of failure. Not something I would suggest doing as a regular way of transporting engines, but it was definitely a great test for us.”

It is easy to see why Longhorn Fab Shop engine stands are the perfect choice to enhance your Ford Powerstroke, Chevy/GMC Duramax, or Dodge Ram diesel engine building operation.

Longhorn Side Mount Engine Stand Adapters

Specific engines require a Side Mount Engine Stand Adapter, which Longhorn Fab also sells separately, to be mounted to the 3/4” front adapter plate. Whether you’re working on a Duramax, Powerstroke, or Dodge diesel engine, Longhorn Fab has you covered! The side mount plate gives you full access to the block allowing for full disassembly. In addition, per Manfred, “We also offer custom designed adapters for shops and industry.”

Maintenance and Safety Precautions

The Longhorn Fab Shop Pro-Grade Rotating Engine Stands do not require any maintenance once they leave their facilities. Per Manfred, “We recommend a visual inspection just like you would for any piece of equipment that you would be operating. Other than that, there is no maintenance required. We adjust everything, do a run-in test, adjust the controls, tighten everything up, and put top of the line grease in the bearings that will last a lifetime.” The stand comes fully assembled, allowing you to rebuild engines right on arrival.

It is important to follow safe shop practices and be mindful when rotating or lifting anything heavy. Per Manfred, “Blocks can be cracked or fire damaged and you want to look over the engine and where you will be mounting it and make sure it is structurally sound. We make it extremely easy to rotate the engine so there is no need to ever be underneath it.” Additionally, never crawl under or put anything under the engine while mounted, as this stand makes it easy to rotate so you don’t have to!

About Longhorn Fab Shop

Founded on the essence of the American Dream, Longhorn Fab Shop is not just another company built on making decisions to please stockholders. It’s a company founded on the belief that success should encompass all involved parties—suppliers, businesses, customers, communities, and future generations of diesel enthusiasts.[4] Longhorn Fab Shop designs, engineers, programs, and manufactures all their products in house in Brookville, Ohio, with the latest software, tools, and American made metals.

Originally specializing in products for Chevy/GMC pickups equipped with Duramax engines, Longhorn Fab offers an array of direct-fit and universal traction bars, along with brackets & hardware. However, their engine stands are what Longhorn Fab takes the most pride in. Drawing from extensive hands-on experience with some of the largest manufacturers in the world, Longhorn Fab continually strives to make your job easier, which is what their engine stands deliver. XDP is proud to be a longtime partner and supplier of Longhorn Fab Shop.

Make your engine rebuild easier with Longhorn Fab Shop’s Pro Grade Rotating Engine Stand! Shop XDP.com today to get one for your shop. See the Longhorn Engine Stand in action on the XDP YouTube channel.

References

- https://www.xtremediesel.com/manuals/Engine%20Stand%20Brochure%20Page%201.pdf

- https://longhornfabshop.com/industrial-rotator-professional-grade-rotating-engine-stand-caster-wheel-201052-c/

- https://www.youtube.com/watch?v=uyUc72_vJJE

- https://longhornfabshop.com/pages/About.html