History/General Info

During the 2003 model year, Ford introduced the all-new 6.0L Powerstroke based on the Navistar International VT365. This highly innovative and powerful engine offered many new features. Equipped with 4 valves per cylinder, as well as upgrades to the turbocharger and fuel injection system, the 6.0L proved to be more powerful than the 7.3L engine it replaced. All this new technology helped land the 6.0L a spot on the Ward’s 10 Best Engine list for the 2003 model year. Despite all the accolades, the 6.0L Powerstroke still carries a mixed reputation with diesel enthusiasts.

6.0L Innovations

One of the major innovations of the 6.0L Powerstroke was the new Variable Geometry Turbocharger (VGT). The VGT provided increased throttle response by the use of a unison ring and variable vanes. The VGT is designed so the housing’s size can essentially change depending on the throttle position. At lower RPMs, the housing is more restrictive for better throttle response. At higher RPMs, the vanes open which allows for improved exhaust flow.

Another big upgrade was new cylinder heads that featured 4 valves per cylinder (up from the 2 valves per cylinder found in the 7.3L). To support all this additional airflow, Ford also upgraded the fuel injection system. The injectors utilized a spool valve now, instead of the poppet valve used on previous engines. The spool valve allowed for a higher oil pressure output and created a more efficient combustion process.

When the 6.0L debuted in 2003, it offered a class-leading 325 hp and 560 lb-ft of torque (570 lb-ft of torque from 2005-2007). This was a 50 hp upgrade over its predecessor. Ford discontinued the use of the 6.0L Powerstroke in their Super-Duty pickups after the 2007 model year, but the engine was still used in E-Series vans up until the 2010 model year.

Transmissions

With the increased power levels Ford paired the 6.0L Powerstroke with some heavy-duty transmission options. For customers that preferred to row their own gears, the ZF S6-650 6-Speed manual transmission was the standard transmission. The 4R100 automatic transmission was replaced with the 5R110W TorqShift transmission. Besides offering one additional gear, this new 5-speed automatic was also stouter and more capable of handling the additional horsepower and torque offered in the 6.0L.

Ford Excursion

The Ford Excursion full-size SUV which debuted in 2000, continued to be offered through 2005. In 2003, both the 7.3L and 6.0L diesel engines were offered (just as in the Super Duty trucks).

Suspension

The Super Duty continued to use leaf springs for the front suspension in 2003 and 2004. Beginning in 2005, a new coil spring front suspension was introduced which helped improve the ride on the 2005-2007 pickup trucks. Radius arms and a track bar were incorporated to keep the Dana 60 solid front axle located properly. The rear suspension retained the leaf spring setup with the Sterling 10.5″ rear differential (Dana 80 in F-350 DRW/F-450 and Dana 135 in F-550 applications).

6.0L Powerstroke Common Problems

Although it was extremely innovative when it debuted in 2003, the 6.0L has earned a reputation for many issues that have plagued them over the years. Many of these common failures can be addressed with upgraded parts available in the aftermarket. Manufacturers have been able to improve upon many of the original design flaws of the engine. Even with all the known problems, they are still a very popular engine and are revered by many.

6.0L Head Gaskets

Anyone that has heard of the Ford 6.0L Powerstroke is most likely familiar with the head gasket issues that they were known for. There are plenty of different theories on why they had so many head gasket failures. Ultimately, the main reason for head gasket issues can be traced back to the original design of the engine. The 6.0L cylinder used only 4 bolts per cylinder (with a total of 10 bolts per side). This was down from 18 per bank on the 7.3L Powerstroke. Besides insufficient cylinder head clamping, the 6.0L was equipped with undersized 14mm Torque-To-Yield (TTY) head bolts that were prone to stretching.

There does not seem to be any direct correlation to the model year. Plenty of trucks with well over 100K+ miles are still on the road and never experienced any head gasket issues. The head gasket issue is something to be aware of, but it should not completely scare you off from purchasing a 6.0L.

Upgrading to head studs and replacing the factory TTY head bolts is strongly recommended when replacing the head gaskets. Head studs are much stronger than the factory head bolts and will solve all the typical head gasket issues. Head studs are an ideal upgrade for stock trucks, and even more imperative for any 6.0L owner that is looking to raise the stock power levels. The cylinder heads should also be sent off to a machine shop and checked before re-installation.

Oil Cooler

The 6.0L utilized a Hydraulic Electronic Unit Injector (HEUI) system that used high-pressure engine oil to actuate the injector, This also circulated oil through the turbocharger. As a result, a lot of additional heat is added to the oil. To keep temperatures under control, an oil cooler was mounted inside the valley of the engine. Oil and coolant were circulated through the cooler with the coolant helping to bring down the oil temperature. Unfortunately, the oil coolers tend to clog or fail over time.

Residual sand not being properly removed from the cooler after the casting process is thought to be a likely contributor leading to the coolers getting clogged. With reduced levels of coolant or no coolant, flowing through the oil cooler, the oil will no longer be properly cooled. A clogged oil cooler can lead to a ruptured EGR cooler, overheated fuel injectors, and other damage. If oil is present in the coolant or coolant in the oil, that can be a sign of oil cooler failure. To reduce the chance of failure, it is important to change your engine oil and coolant closely following Ford’s recommended maintenance schedule. Adding a coolant filtration system to remove contaminants from the cooling system is highly recommended on the 6.0L.

Oil Cooler Testing

To determine if the oil cooler is still working properly, testing can be performed using electronic diagnostic equipment or a digital monitor such as an Edge CTS2/CTS3. By monitoring the delta temperature between the Engine Oil Temperature (EOT) and Engine Coolant Temperature (ECT) you can get some insight into how well the oil cooler is functioning. With a stock oil cooler, you typically do not want to see more than a 14° delta. So, if the coolant is 196°, the oil temp should not go above 210°. If you see ECT and EOT temperature differences that exceed 15° that is a sign the oil cooler may need to be replaced. Note, this testing should be done carefully while driving the vehicle at wide-open throttle (WOT) or under high load to achieve maximum boost, and the ECT temperatures should be above 190°.

EGR Cooler

The EGR cooler is another part that can be prone to failure and eventually need replacement. If the oil cooler fails it can prevent adequate coolant from reaching the EGR cooler and lead to catastrophic failure. If the EGR cooler cracks, you may begin to see white smoke at idle when the EGR valve opens. This is because the engine will be burning coolant that is now entering the intake manifold. The 2003-2004 6.0L utilized a round EGR cooler (up until 9/22/03). In 2004 Ford switched over to a square EGR cooler design.

ICP/IPR Sensor Issues

The Injection Control Pressure (ICP) sensor and Injection Pressure Regulator (IPR) are other common sources of issues found on the 6.0L. These two sensors are essential for the proper function of the HEUI injection system. When these sensors fail, it can lead to poor idling, stalling, surging, and can even prevent the engine from starting. Compounding the problem, they may not be particularly easy to access, especially the ICP sensor on early engines.

2003 and early 2004 model years featured the ICP located behind the turbocharger and beneath the turbocharger up-pipe collector. The ICP was relocated to the passenger side valve cover during the 2004 model year, which provided easier access. If you remove the ICP plug/harness and see oil-soaked contamination on the electrical terminals that is a sign the sensor has failed. ICP sensor wiring pigtails are available and replacement is oftentimes recommended when oil has saturated the connector.

Fuel Injection Control Moduel (FICM)

The Fuel Injection Control Module (FICM) is mounted to the driver-side valve cover and is subjected to heat and vibration. As a result, FICM failure is very common on the 6.0. If your FICM is not putting out over 48 volts, it probably needs to be replaced. The FICM voltage can be checked with electronic diagnostic equipment.

High-Pressure Oil Pumps (HPOP)

The High-Pressure Oil Pump (HPOP) on the 6.0L Powerstroke has been known to malfunction, especially in the earlier model years. As the O-rings and other seals wear out over time, the oil can leak and start causing driveability issues. Scan tools or digital monitors can be used to check the HPOP and see if it is operating within factory specifications. At wide-open throttle (WOT), oil pressure should read between 3,000 and 4,000 psi. At idle, oil pressure is typically in the 600-700 psi range. A minimum of 500 psi is required to fire the injectors, if pressure drops below that, the engine will stall. If the pressure is too low, it can also prevent the engine from starting.

What To Look For When Purchasing a 6.0L

The service history or receipts of the work that has been performed can be very important when purchasing a truck with a 6.0L Powerstroke. This can help clue you in on what type of repairs/upgrades still might be due in the future. Next, doing adequate research on the 6.0L and having the ability to perform some basic diagnostic tests prior to purchasing can be very beneficial as well. As with most trucks, rust can be a common issue. The pickup bed, rocker panels, and bottom of the doors are some of the typical areas that are prone to rust/rot.

Pros/Cons

Pros

- 4 Valves Per Cylinder

- Highly Advanced Diesel Engine

- Variable-Geometry Turbocharger (VGT)

- Class-Leading Horsepower & Torque in 2003

- Integrated Trailer Brake Controller Option (Introduced in 2005)

Cons

Common Failure Prone Components –

- FICM

- Oil Cooler

- EGR Cooler

- Head Gasket

- ICP/IPR Sensor

- High-Pressure Oil Pump (HPOP)

- Turbocharger – Sticking VGT Vanes

Review

Although the 6.0L has a much-maligned reputation for all its shortcomings, it is still a very desirable engine for many enthusiasts. All the typical 6.0L-specific issues can be addressed from a wide selection of aftermarket upgrades that are available. It is extremely important to closely follow the factory maintenance schedule on a 6.0L. This can help reduce the number of problems you experience.

6.0L Powerstroke Popular Aftermarket Upgrades

The following is a list of popular upgrades to increase the reliability and add power to your 6.0L Powerstroke. Many of these parts also address some of the common issues from the factory.

1. Coolant Filtration System

Contaminants such as casting sand and sediment that are present in the cooling system can cause damage. A Coolant Filtration System helps remove these contaminants and can extend the life of your coolant, water pump, EGR cooler, and other vital components.

2. ARP Head Studs

If you are replacing the head gaskets on your 6.0L, or if you have plans to turn up the power ARP Head Studs are a must-have upgrade.

3. Oil Cooler

A part that is especially prone to failure, the oil cooler can get clogged up creating hotter-than-normal Engine Oil Temperatures. A failed oil cooler can also lead to oil in the coolant, or coolant in the oil.

4. EGR Cooler

Another common failure item, white smoke at startup or during idle can be a sign your EGR cooler has failed.

5. High-Pressure Oil Pump (HPOP)

At some point for every 6.0L, the HPOP can eventually fail, or at a minimum, the gaskets and seals might need replacement. The HPOP was revised during the 2004 model year with the later units being a little more reliable.

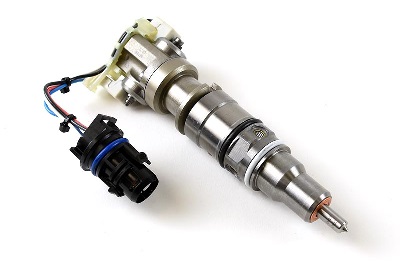

6. Fuel Injectors

The 6.0L Powerstroke is known to experience fuel injector failure, especially since they rely on proper oil pressure to operate. If your injectors fail, make sure to upgrade with a high-quality fuel injector.

7. Turbocharger

The moving parts of the VGT inside of the turbocharger are prone to wear as well as rust and carbon build-up. When the turbo on your 6.0L begins to stick, you’ll feel some noticeable lag in turbo response and a general loss of power.

8. Blue Spring Upgrade Kit

Elevate the fuel pressure in your 6.0L and increase overall performance, drivability, and help to prevent damage to your injectors, while increasing the longevity of vital fuel system components. The Blue Spring Upgrade Kit can increase pressure by around 10 psi and is the perfect upgrade for any stock or modified truck.

9. Oil Additive

Oil Additives in any diesel can help reduce engine wear, improve fuel economy, and reduce oil operating temperatures. On the 6.0L Powerstroke engine, it is even more beneficial as it can eliminate stiction and help restore your failing HEUI injectors.

10. Exhaust

Reduce backpressure, lower EGTs, and get the most from your cold-air intake and programmer/tuner with an aftermarket exhaust.

11. Air Intake System

Installing an Air Intake System and increasing the amount of cool dense air will help improve the performance and efficiency of your diesel engine.

12. Programmer/Tuner

Not only can you add power and torque to your 6.0L some programmers also function as a complete gauge package to let you monitor vital engine and transmission data in real time.

2003-2007 Ford 6.0L Powerstroke Specifications

| Production Years: | 2003, 2004, 2005, 2006, 2007 (production continued for 2008, 2009, and 2010 in Ford E-Series Vans) | |

| Model Availability: | F250, F350, F350, F450, F550, Excursion, E350, E450 | |

| Common Names: | 6.0, 6.0L, Powerstroke, Navistar VT365 | |

| Configuration: | V8 | |

| Displacement: | 365 cubic inches, 6.0 liters | |

| Bore: | 3.74″ (95mm) | |

| Stroke: | 4.134″ (105mm) | |

| Cylinder Head: | Cast Iron w/ Four 14mm Head Bolts Per Cylinder (10 Per Bank) | |

| Engine Block: | Cast Iron | |

| Firing Order: | 1-2-7-3-4-5-6-8 | |

| Compression Ratio: | 18.0 : 1 | |

| Pistons: | Cast Aluminum | |

| Connecting Rods: | Forged Steel | |

| Injection: | Direct injection, Electro-Hydraulic Generation Two (G2) Injection Technology (HEUI injectors, 26,000 psi) | |

| Fuel Pump: | Electric Low-Pressure Lift Pump | |

| Turbocharger: | Garrett GT3782VA Variable Geometry Turbocharger (VGT) | |

| Valvetrain: | 4 Valves Per Cylinder (32 Valve Pushrod Valvetrain) | |

| Weight: | Approx. 966 lbs | |

| Oil Capacity: | 15 qts w/ Filter (14.2L) | |

| Horsepower: | 2003-2007 | 325 HP @ 3,300 RPM |

| Torque: | 2003-2004 | 560 lb-ft @ 2,000 RPM |

| 2005-2007 | 570 lb-ft @ 2,000 RPM | |

| Battery: | Group Size 65 | |

| Transmissions: | ZF S6-750 6-Speed Manual | |

| 5R110W (TorqShift) 5-Speed Automatic |

Fluid Specifications & Capacities

| Engine Oil: | 15W-40 | Acceptable viscosity in ambient temps > 10° F Preferred viscosity in ambient temps > 30° F | 15.0 Qt Capacity w/ Oil Filter (14.2L) |

| 10W-30 | Acceptable viscosity in ambient temps -10 to 90° F Preferred viscosity in ambient temps -10 to 30° F | 15.0 Qt Capacity w/ Oil Filter (14.2L) | |

| 5W-30 | Acceptable viscosity in ambient temps < 30° F | 15.0 Qt Capacity w/ Oil Filter (14.2L) | |

| 0W-30 | Acceptable viscosity in ambient temps < 0° F | 15.0 Qt Capacity w/ Oil Filter (14.2L) | |

| Engine Oil API Category: | CI-4/CH-4 or equivalent | ||

| Engine Coolant: | Motorcraft VC-7-B (Gold Engine Coolant) | 27.5 Qt Capacity (6.875 Gallons) | |

| Automatic Transmission Fluid: | 5R110W (TorqShift) 5-Speed | Mercon SP ATF | 17.5 Qt |

| Manual Transmission Fluid: | ZF S6-750 6-Speed | Mercon V ATF | 5.8 Qt |

| Transfer Case Fluid: | NP271/NP273 | Motorcraft XL-12 (Replaced by Mercon LV) | 2.0 Qt |

| Front Differential Fluid: | Dana 60 Front | SAE 80W-90 | 3.0 Qt |

| Rear Differential Fluid: | Sterling 10.50″ Rear (F-250/350 SRW) | SAE 75W-140 | 3.45 Qt |

| Dana 80 Rear (F-350 DRW/F-450) | SAE 75W-90 | 4.25 Qt | |

| Dana 135 Rear (F-550) | SAE 80W-90 | 12.25 Qt | |

| Limited Slip Additive: | Motorcraft XL-3 Friction Modifier | ||

| Brake Fluid: | DOT-3 Brake Fluid | Fill To Reservoir Marker | |

| Power Steering Fluid: | MERCON V ATF | Fill To Correct Dipstick Level |

Filters

| Air Filter | Motorcraft FA-1778 |

| Engine Oil Filter | Motorcraft FL-2016 |

| Fuel Filter | Motorcraft FD-4616 |

| 5R110W Transmission Filter (Internal) | Motorcraft FT-144 |

| 5R110w Transmission Filter (External) | Motorcraft FT-145 |

Maintenance Schedule

| Service Procedure | Interval |

| Replace Engine Oil & Filter: | 7,500 miles/6 months under normal driving conditions 5,000 miles/6 months under severe driving conditions |

| Replace Fuel Filter: | 15,000 miles |

| Replace Air Filter: | Monitor Air Filter Minder (mounted to air filter housing) |

| Engine Cooling System: | Initial Service – 100,000 miles/5 years Subsequent Service – 45,000 mile/3 years (Motorcraft Gold Engine Coolant) |

| Replace Automatic Transmission Fluid & Filter: | 30,000 miles |

| Replace Manual Transmission Fluid: | 60,000 miles |

| Replace Transfer Case Fluid: | 150,000 miles under normal operating conditions 60,000 miles under severe duty conditions |

| Replace Front Differential Fluid (4×4) | 100,000 miles under normal operating conditions 30,000 miles under severe duty conditions |

| Replace Rear Differential Fluid | 100,000 miles under normal operating conditions 30,000 miles under severe duty conditions |