History/General Info

The Duramax LBZ was introduced for the 2006 model year and eventually retired halfway through the 2007 model year but remains an extremely popular choice with diesel enthusiasts to this day. The GM 6.6L Duramax engine was completely redesigned to enhance overall performance and reliability for 2006. The LBZ engine tuning resulted in a significant increase in horsepower and torque, with the power levels getting a bump to 360 hp and 650 lb-ft of torque, up from 310 hp and 605 lb-ft of torque in the LLY.

Solid Foundation

The solid foundation of a cast-iron block and aluminum heads were carried over, but they received numerous upgrades in 2006. The cast-iron block received casting and machining changes to help strengthen the bottom of the cylinder bores. Preparing for additional horsepower and torque, more webbing was now cast into the main bearing areas of the block. Taller main bearing caps and deeper bores for the main cap bolts were also employed. Minor changes were also made to the crankshaft, along with the use of a new reluctor wheel.

In addition, the engine internals were revised for additional durability. The forged steel connecting rods with a cracked capped construction were similar to previous iterations but were reinforced to handle the increase in horsepower and torque. The I-beam style connecting rods featured more material in critical areas to increase their overall strength. New cast-aluminum pistons were also utilized to lower the compression ratio.

LBZ Upgrades

One of the main components to the increase in power was upgrades to the common-rail fuel system. The reliable Bosch CP3 injection pump was still used but maximum pressure increased from 23,000 psi to more than 26,000 psi. The Bosch solenoid-style fuel injectors were updated to a 7-hole nozzle that sprayed fuel directly onto the new fast-heat glow plugs when cold to provide faster start-up. A larger turbocharger inlet manifold was added to help lower intake and exhaust temperatures while improving responsiveness from the Garrett GT3788VA variable-vane turbocharger (VVT). This was also the first application to use a new 32-bit E35 controller, which adjusts and compensates for the fuel flow to bolster efficiency. The combination of new mechanical components and an upgraded ECM made the 2006-2007 Duramax LBZ the most reliable, durable, and powerful Duramax up to that point.

Transmissions

The LBZ was the first Duramax to be coupled to the 6-speed Allison 1000 automatic, which proved capable of handling more power than the five-speed version that preceded it. The ZF650 6-speed manual transmission was still available, but the diesel market started to favor automatic transmissions and 2007 was the last year a Duramax diesel engine was offered with a manual transmission. The 2007.5 Duramax LMM was not available with a manual transmission.

Express/Savana

The LBZ was the first Duramax diesel to be offered in the Chevrolet Express and GMC Savana 2500/3500 vans. The vans featured a slightly detuned version of the Duramax diesel and were only offered with a GM 4L80E/4L85E 4-speed automatic.

LBZ Issues

Whereas the rods were the weak link in the LB7 and LLY mills, things were reversed in the LBZ. The cast-aluminum pistons are prone to cracking, especially when the power level is increased. Most failures occur in engines where larger injectors and turbo have been installed. The pistons typically cracked along the centerline of the wrist pin.

Similar to what many Ford 6.0L Powerstroke owners experience, the Garrett GT3788VA VVT is known for turbo vanes that can get stuck. It typically happens when corrosion and carbon accumulation cause the unison ring to seize. With limited or no travel in the unison ring, it will typically lead to poor drivability and a significant decrease in power.

Plastic water pump impellers were introduced on late model LLY engines and came equipped on the LBZ as well. The impellers are pressed onto the pump’s steel shaft and can spin on the shaft causing overheating issues. Even with some inherent issues, most plastic impeller water pumps can still manage to last between 150,000 to 200,000 miles. Water pump failure is not always due to the plastic impeller, many fail due to a bad pump seal.

What To Look For When Purchasing

Just like the previous years, the 2006-2007 GM 2500HD/3500HD models came equipped standard with a Vortec 6.0L gas engine and offered two optional engine choices, the 8.1L big block or the 6.6L Duramax LBZ. The Duramax diesel is the most desirable drivetrain and will command a large premium over the two gas-powered choices.

With any older pickup, they are especially prone to rust. If the truck spent any time in a region that gets snow thoroughly examine the frame for rust/rot. The bedsides, rocker panels, and cab corners are also common areas for rust. Also, the brake, fuel, and transmission lines are known to get rusty over time and can rupture or leak. If leaks occur it can cause a potential safety hazard.

Pros/Cons

Pros

- Stronger Block and Rods

- Allison 6-Speed Automatic Transmission

- Common Rail Fuel System with CP3 Pump

- IFS Provides a Smooth & Comfortable Ride

Cons

- Weak Pistons

- Body/Frame Rust

- Water Pump Failure

- Turbo Vanes That Stick

- Brake/Fuel/Trans Lines Prone to Rust

Review

The 2006-2007 GM 6.6L Duramax LBZ equipped vehicles are extremely sought after and desirable with Duramax enthusiasts still to this day. They offer an excellent combination of a strengthened bottom-end and respectable power from the factory with plenty of aftermarket parts and support. The 6-speed Allison transmission is another big selling point for these trucks. As with any older pickup, buying a truck without rust issues can be difficult, depending on your location. If you purchase a truck with rust issues a wide selection of repair panels are readily available in the aftermarket.

Popular Aftermarket Upgrades

The LBZ has become a popular choice for performance enthusiasts due to the engine’s strengthened design, an abundance of aftermarket support, and its reasonably high factory performance.

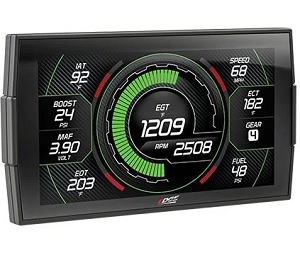

1. Programmer/Tuner

Besides increasing horsepower and torque many Programmers/Tuners can also act as a complete gauge package and monitor your vital engine and transmission data in real-time.

2. Air Intake System

Aftermarket Air Intake Systems are designed to provide a smoother and straighter airflow. This allows your vehicle’s engine to inhale a larger volume of air than the restrictive stock air filter assembly. More air means more power throughout the engine’s RPM range.

3. Exhaust

Upgrade your exhaust with mandrel-bent tubing for maximum flow, increased horsepower & torque, plus lower EGT’s.

4. Lift Pump

The LBZ Duramax doesn’t have a lift pump to supply the engine with fuel, as the CP3 pump does double duty and has to pull fuel from the tank. This can fail to adequately supply fuel, especially to a modified engine and can add excessive wear to the CP3 pump.

5. Fuel Filter Delete

A fuel filter delete is a must-have for any 6.6L Duramax with a modified fuel system. Installs in place of your factory fuel filter when using aftermarket fuel systems such as an Airdog, FASS, or custom applications where your factory fuel filter is no longer needed.

6. Crankshaft Pin Kit

The factory dowel pin is known to shear easily causing the balancer to spin on the snout of the crankshaft. When the balancer spins, it can throw off the balance of the engine and create harsh vibrations. Continued operation in these conditions will likely result in serious engine damage such as a broken crankshaft. Pin your crankshaft so the balancer stays in place and eliminates the risk of damage.

7. Upgraded Tie Rods Ends or Sleeves

Tie Rod Sleeves or Upgraded Tie Rods are a must-have for your high-performance Silverado/Sierra. The factory tie rods are known to bend under the added stress of lifted torsion bars, increased horsepower and torque, and aggressive tires.

8. Turbo Inlet/Intake Mouthpiece

An upgraded Turbo Inlet/Intake Mouthpiece can provide you with increased performance, throttle response, and better overall drivability.

9. Drivers Side High-Flow Exhaust Manifold

Ditch the restrictive factory driver’s side exhaust manifold and improve the exhaust flow with a high-flow exhaust manifold.

10. Radiator

With the age of these trucks, there is a good chance the radiator will need replacing sooner rather than later. The fact these trucks had cooling issues from the get-go is another reason to make sure your cooling system is at operating at its peak performance.

2006-2007 GM 6.6L Duramax LBZ Specifications

| Production Years: | 2006, 2007 | |

| Model Availability: | Chevrolet Silverado 2500HD, 3500HD GMC Sierra 2500HD, 3500HD Chevrolet Express 2500, 3500, 4500 GMC Savana 2500, 3500, 4500 | |

| VIN Code: | D (8th digit of VIN) | |

| Common Names: | LBZ, Duramax | |

| Configuration: | V8 | |

| Displacement: | 403 cubic inches, 6.6 liters | |

| Bore: | 4.055″ (103 mm) | |

| Stroke: | 3.897″ (99 mm) | |

| Cylinder Heads: | Aluminum | |

| Engine Block: | Cast Iron | |

| Firing Order: | 1-2-7-8-4-5-6-3 | |

| Compression Ratio: | 16.8 : 1 | |

| Pistons: | Cast Aluminum | |

| Connecting Rods: | Forged Steel w/ Cracked Cap Design | |

| Aspiration: | Turbocharged & Intercooled | |

| Injection: | High-Pressure Common Rail / Direct Injection | |

| Fuel Pump: | Bosch CP3 Injection Pump | |

| Fuel Injectors: | Piezo Electric Fuel Injectors (7-hole) | |

| Turbocharger: | Garrett GT3788VA – Variable Vane Turbocharger (VVT) | |

| Valvetrain: | OHV, 4 Valves Per Cylinder | |

| Idle Speed: | 680 rpm | |

| Max Engine Speed: | 3,400-3,450 (rev limiter) | |

| Weight: | Approx. 835 lbs (Dry) | |

| Oil Capacity: | 10 qts w/ Filter (9.46L) | |

| Horsepower: | Silverado/Sierra | 360 hp @ 3,200 rpm |

| Express/Savana | 250 hp @ 2,500 rpm | |

| Kodiak/Topkick | 310 hp @ 3,000 rpm | |

| Torque: | Silverado/Sierra | 650 lb-ft @ 1,600 rpm |

| Express/Savana | 460 lb-ft @ 1,600 rpm | |

| Kodiak/Topkick | 605 lb-ft @ 1,600 rpm | |

| Battery: | Group Size 78 | |

| Transmissions: | ZF S6-650 (6-Speed Manual) | |

| Allison 1000 (5-Speed Automatic) | ||

| 4L80E/4L85E (4-Speed Automatic) | Express/Savana Vans |

Fluid Specifications & Capacities

| Engine Oil: | 15W-40 | Preferred viscosity, ambient temp > 0° F | 10.0 qts Capacity w/ Oil Filter (9.46L) |

| 5W-40 | Preferred viscosity, ambient temp < 0° F, acceptable in all temps | 10.0 qts Capacity w/ Oil Filter (9.46L) | |

| 10W-30 | 100° F > ambient temp > 0° F | 10.0 qts Capacity w/ Oil Filter (9.46L) | |

| Engine Coolant: | 50/50 Dex-Cool Engine Coolant, Distilled Water | 22.0 – 31.4 quarts (5.5 – 7.85 gallons) Refer to owner’s manual for application specific coolant capacity | |

| Automatic Transmission Fluid: | Allison 1000 (6-Speed) | Dexron VI Automatic Trans Fluid | 7.4 qts service refill 12.7 qts total capacity |

| Manual Transmission Fluid: | ZF S6-650 (6-Speed) (2006 Model Year Only) | GM TranSynd Full Synthetic | 5.8 qts |

| Transfer Case Fluid: | Manual Shift | Dexron VI Automatic Trans Fluid | 2.0 qts |

| Automatic Shift | AUTO-TRAK II | 2.0 qts | |

| Front Differential Fluid: | 9.25″ IFS (14 Bolt) | SAE 75W-90 | 1.8 qts |

| Rear Differential Fluid: | AAM 9.5″ (14 Bolt) | SAE 75W-90 | 2.7 – 2.8 qts |

| GM 10.5″ (14 Bolt) | SAE 75W-90 | 3.2 – 3.5 qts | |

| AAM 11.5″ (14 Bolt) | SAE 75W-90 | 4.4 – 5.0 qts |

Maintenance Schedule

| Service Procedure | Interval |

| Replace Engine Oil & Filter: | 10,000 miles or when “change engine oil” message is displayed by the oil life monitoring system |

| Replace Fuel Filter: | 15,000 miles |

| Replace Air Filter: | Check filter condition every oil change and replace as necessary; replace at 45,000 miles regardless |

| Flush Engine Cooling System: | 150,000 miles |

| Replace Automatic Transmission Fluid & Filter: | 50,000 miles (normal conditions) 25,000 miles (severe duty conditions) |

| Replace Manual Transmission Fluid: | 60,000 miles |

| Replace Transfer Case Fluid: | 50,000 miles |