History/General Info

In 2008, Ford introduced an all-new 6.4L Powerstroke based on the Navistar MaxxForce 7. This new 6.4-liter diesel V8 was cleaner, quieter, and more powerful than its 6.0L predecessor. It featured a few firsts for a Ford diesel engine such as common-rail fuel injection and a diesel particulate filter (DPF). One of the most exciting new features was a compound turbocharger setup, which was a first for any diesel engine in the light truck market. Unfortunately, similar to the 6.0, it suffered with reliability issues and carries a mixed reputation with diesel enthusiasts. The 6.4L ended up being the last International Navistar diesel engine used in a Super Duty truck.

6.4L Innovations

Like the 6.0L Powerstroke, the 6.4L utilized a cast-iron cylinder block and a cast-iron bed plate that eliminated traditional main bearing caps. This bed plate is securely bolted to the engine block with four bolts per main. The 6.4 came equipped with powdered metal connecting rods which were an upgrade over the 6.0 connecting rods. On the top end, it continued to use cast iron cylinder heads with four valves per cylinder. Like the 6.0L, the cylinder heads have just four head bolts per cylinder, but utilized 16 mm head bolts instead of 14 mm. This upgrade was most likely a result of the head gasket issues that plagued the 6.0 for years. This new Powerstroke continued to use a conventional single cam-in-block and overhead valve (OHV) pushrod valvetrain. Valves are actuated by the rocker arms, with each rocker arm opening and closing two valves at once.

The 6.4L Powerstroke engine moved from the Hydraulic Electronic Unit Injectors (HEUI) to a direct high-pressure common rail fuel injection system. A Siemens VDO K16 high-pressure fuel pump located at the rear of the lift valley was responsible for supplying the fuel. The engine was also the first in the segment with piezoelectric injectors. These injectors offered more precise fueling than the HEUI injectors and were capable of pulling off five events during the course of each cylinder’s powerstroke. These injectors also helped to improve cold starting.

Compound Turbochargers

One of the biggest highlights of the 6.4 Powerstroke was the new compound turbochargers. This setup consisted of two V2S turbochargers manufactured by BorgWarner. It utilizes a 65 mm fixed geometry low-pressure unit with a 52 mm variable geometry high-pressure turbocharger. This system offered benefits such as reduced turbo lag and improved performance.

EGR/DPF

The 6.4L also received a revised exhaust gas recirculation (EGR) system now featuring two EGR coolers. Almost 25 percent of the intake air contained exhaust gases now, helping to lower NOx emissions. To reduce particulate matter production, it also received a Diesel Particulate Filter (DPF) for the first time. A special regeneration process for the DPF made it a self-cleaning device. During that active regeneration process, additional fuel is injected into the engine’s exhaust stroke to effectively burn out the trapped particles in the DPF.

Transmissions

The ZF S6-650 6-Speed manual transmission and 5R110W TorqShift automatic transmission were both carried over from the 6.0L Powerstroke. Slight changes to the 5R110 trans included a new deeper transmission pan with an improved filter. This revised filter and pan have become a popular upgrade for 2003-2007 truck owners.

6.4L Powerstroke Common Problems

Since the 6.4L was based on the same basic architecture as the 6.0L, it could be argued it retained some of the good and bad design features as well. The 6.4L Powerstroke is perhaps the best you could achieve from the previous 6.0L version in terms of reliability. Unfortunately, the 6.4 still had a lot of similarities in the design with the problematic 6.0L predecessor.

Cracked Pistons

The factory pistons are a weak point in the engine design and are prone to cracking. This can possibly be attributed to the high 40-42 psi stock boost pressure as well. Although the 6.4L engine featured more durable connecting rods, the pistons were not up to the task.

6.4L Head Gaskets

Problems with blown head gaskets were not as common as the 6.0L, but can still occur due to stretched head bolts under higher cylinder pressure. The size of head bolts on the 6.4L were increased from 14mm to 16mm so the design was improved, but the head gasket issues were not completely resolved.

Lack of Lubrication For The Rocker Arms

Another issue that has been seen on many 6.4L’s is a lack of oil lubrication for the rocker arms. In any case, this leads to accelerated wear of the pressed-in balls of the rocker arms, increased friction, and heat in the valve train.

Oil Cooler Clogging

The 6.4L features an oil cooler similar to the 6.0L and can also be prone to clogging. A failed oil cooler can eventually block coolant flow to the EGR cooler, causing the EGR cooler to fail.

Fuel Dilution of the Engine Oil / Cylinder Washing

Sometimes a small amount of fuel can mix with the engine oil in the 6.4L as a result of the DPF regeneration process. It’s not uncommon for owners to report draining an extra gallon at a regularly scheduled oil change interval. Diluting engine oil with diesel fuel can cause serious damage to vital components such as the main and rod bearings, in addition to the turbochargers, valvetrain, and more.

Cracked Exhaust Up-Pipe Expansion Joints

Cracked up-pipes can also be a common issue on the 6.4L. They are known to crack at the bellows (or expansion joints). As a result, this causes a loss of drive pressure, a drop in boost, and poor drivability. Common symptoms can include soot on the firewall and transmission tunnel and can usually be detected by an audible whistle.

Front Cover Cavitation Failure

The front cover is bolted to the front of the engine block and features a machined surface where the water pump mounts. The water pump impeller is located within this machined area and as it spins coolant is circulated throughout the engine. One major downside to this system is that hot EGR coolant comes back into the system here, after cooling the exhaust gas. In this case, the super-heated coolant can cause cavitation and over time erosion can create a small hole in the aluminum front cover. Eventually a hole can develop and coolant can sneak through to the crankcase and start to contaminate the engine oil.

A simple test can be performed to help determine if your front cover has failed from cavitation. First, begin by draining your engine oil and leave the drain plug removed. Subsequently, do a simple pressure test on the cooling system and check to see if any coolant starts to come out of the oil pan drain hole.

HFCM Fuel-Water Separator Issues

The 6.4L Powerstroke features a Horizontal Fuel Conditioning Module (HFCM). This assembly contains the first filter in the fuel system and features a valve to drain water from the fuel system. Unfortunately, this can be prone to clogging, especially if the water wasn’t drained on a regular basis. Furthermore, as water collects in the bowl of the separator, it mixes with diesel fuel and tends to coagulate, producing a thick sludge that can clog the drain valve. If this occurs, it can be difficult to drain the water and eventually can allow water to enter the fuel system. This can result in damage to the high-pressure fuel system. In any case, to help avoid these problems, draining the fuel-water separator should be done frequently.

Finally, if you are purchasing a truck and do not know how often the water was drained from the system, the front manifold/cover can be removed from the HFCM for a closer inspection. With the cover removed you can physically check to see how much sludge is built up in this compartment. The cavity can be cleaned, or new HFCM assemblies are also available.

Leaking Radiator

Leaks commonly develop at the ends of the radiator where the crimps holding the plastic end tanks can work loose overtime, allowing the two to partially separate. Some also attribute these crimp failures to the upper radiator support allowing too much flex to occur. New stock-style replacement radiators and upgraded units are readily available. In addition, stronger upper radiator support bars are also offered by the aftermarket to help decrease the amount of twisting in the radiator support. Body mounts can also begin to deteriorate over time which can also contribute to potential radiator damage.

Pros/Cons

Pros

- Very Easy To Add Power

- Factory Compound Turbocharger System Is Great For Response & Top-End Power

- Common-Rail Fuel Injection Means More Horsepower, Torque, And Also A Quieter Engine

Cons

- Poor Fuel Economy

- Engines Are Expensive To Fix

- Rarely Does The 6.4L Make It Past 200,000 Miles Without Needing Major Repair

6.4L Review

Although the 6.4L has a much-maligned reputation for all its shortcomings, it is still a very desirable engine for many enthusiasts. All the typical 6.4 specific issues can be addressed from a wide selection of aftermarket upgrades that are available. Finally, it is extremely important to closely follow the factory maintenance schedule which can help reduce the number of problems you experience.

6.4L Powerstroke Popular Aftermarket Upgrades

1. Dash Mounted Tuner/Hand-Held Programmer

Not only can you add power and torque to your 6.4L some tuners/monitors can also function as a complete gauge package to let you monitor vital engine and transmission data in real time.

2. Air Intake System/Cold Air Kit

Installing an Air Intake System and increasing the amount of cool dense air will help improve the performance and efficiency of your diesel engine. Hence the reason cold air kits are so popular on all vehicles.

3. Exhaust

Reduce backpressure, lower EGTs, and get the most from your cold-air intake and programmer/tuner with an aftermarket exhaust.

4. Coolant Filtration System

Due to the cast engine design, traces of casting sand and sediment could be left over after the engine was manufactured. These contaminants are known to damage components in the cooling system. A Coolant Filtration System helps extend the life of your coolant, water pump, EGR coolers, and other vital components.

5. Radiator

As mentioned earlier, these trucks are known for radiators that can develop leaks. One common issue is the ends of the radiator where the crimps holding the plastic end tanks will loosen up over time.

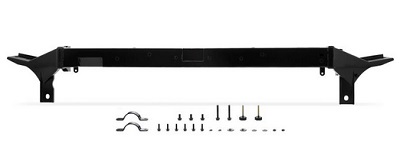

6. Upper Support Bar

This direct-fit upper radiator support crossmember bar helps minimize front-end flex and improve your trucks rigidity. As has been noted, this can help prevent your radiator from twisting and help to prevent end tank separation.

7. Body Mounts

Worn body mounts can begin to cause body alignment issues, and many other problems. This can include issues such as body roll, door rattling, shifting issues, and even problems with components that attach to the body and chassis like the radiator.

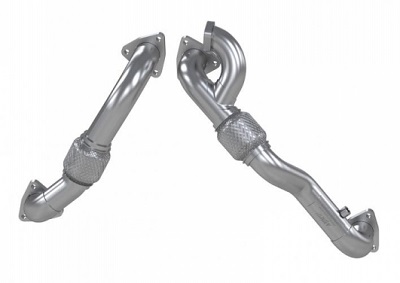

8. Up-Pipes

Over time, the factory up-pipes in the 6.4 are known to leak, crack, or fail which will result in a loss of power. The aftermarket helps address these problems by replacing the failure prone factory part with a more durable version.

9. Oil Cooler

Another common failure item on the 6.4, the oil cooler is prone to clogging from debris in the cooling system. For the same reason as the 6.0, the oil cooler can require eventual replacement.

10. EGR Cooler

Another failure-prone item is the EGR Cooler. Over time they can crack and allow coolant to mix with the exhaust.

2008-2010 Ford 6.4L Powerstroke Specifications

| Production Years: | 2008, 2009, 2010 |

| Model Availability: | F250, F350, F350, F450, F550 |

| Common Names: | 6.4, 6.4L, Powerstroke, Navistar MaxxForce 7 |

| Configuration: | V8 |

| Displacement: | 390 cubic inches, 6.4 liters |

| Bore: | 3.87″ (98.2 mm) |

| Stroke: | 4.134″ (105mm) |

| Cylinder Head: | Cast Iron w/ Four 16mm Head Bolts Per Cylinder (10 Per Bank) |

| Engine Block: | Cast Iron |

| Firing Order: | 1-2-7-3-4-5-6-8 |

| Compression Ratio: | 17.5 : 1 |

| Pistons: | Cast Aluminum |

| Connecting Rods: | Powdered Steel |

| Fuel Injection: | High-Pressure Common-Rail, Siemens K16 VDO Injection Pump with Piezo-Electric Injectors |

| Turbocharger: | Turbocharged, BorgWarnerTwin Sequential Turbochargers (65mm Fixed Geometry Turbocharger & 52mm Variable Geometry Turbocharger) Air-To-Air Intercooler |

| Valvetrain: | 4 Valves Per Cylinder (32 Valve Pushrod Valvetrain) |

| Weight: | Approx. 1,130 lbs |

| Oil Capacity: | 15 qts w/ Filter (14.2L) |

| Horsepower: | 350 HP @ 3,000 RPM |

| Torque: | 650 lb-ft @ 2,000 RPM |

| Battery: | Group Size 65 |

| Transmissions: | ZF S6-750 6-Speed Manual |

| 5R110W (TorqShift) 5-Speed Automatic |

Fluid Specifications & Capacities

| Engine Oil: | 15W-40 | Acceptable viscosity in ambient temps > 10° F Preferred viscosity in ambient temps > 30° F | 15.0 qts Capacity w/ Oil Filter (14.2L) |

| 10W-30 | Acceptable viscosity in ambient temps -10 to 90° F Preferred viscosity in ambient temps -10 to 30° F | 15.0 qts Capacity w/ Oil Filter (14.2L) | |

| 5W-30 | Acceptable viscosity in ambient temps < 30° F | 15.0 qts Capacity w/ Oil Filter (14.2L) | |

| 0W-30 | Acceptable viscosity in ambient temps < 0° F | 15.0 qts Capacity w/ Oil Filter (14.2L) | |

| Engine Oil API Category: | API CJ-4/SM or equivalent | ||

| Engine Coolant: | Motorcraft VC-7-B (Motorcraft Gold Engine Coolant) | 27.5 Qt Capacity (6.875 Gallons) | |

| Automatic Transmission Fluid: | 5R110W (TorqShift) 5-Speed | Mercon SP ATF | 17.5 qts |

| Manual Transmission Fluid: | ZF S6-750 6-Speed | Mercon V ATF | 5.8 qts |

| Transfer Case Fluid: | NP271/NP273 | Motorcraft XL-12 (Replaced by Mercon LV) | 2.0 qts |

| Front Differential Fluid: | Dana 60 Front | SAE 80W-90 | 3.0 qts |

| Rear Differential Fluid: | Sterling 10.50″ Rear (F-250/350 SRW) | SAE 75W-140 | 3.45 qts |

| Dana 80 Rear (F-350 DRW/F-450) | SAE 75W-90 | 4.25 qts | |

| Dana 135 Rear (F-550) | SAE 80W-90 | 12.25 qts | |

| Limited Slip Additive: | Motorcraft XL-3 Friction Modifier | ||

| Brake Fluid: | DOT-3 Brake Fluid | Fill To Reservoir Marker | |

| Power Steering Fluid: | MERCON V ATF | Fill To Correct Dipstick Level |

Maintenance Schedule

| Service Procedure | Interval |

| Replace Engine Oil & Filter: | 7,500 miles/6 months under normal driving conditions 5,000 miles/6 months under severe driving conditions |

| Replace Fuel Filter: | 15,000 miles |

| Replace Air Filter: | Monitor Air Filter Minder (mounted to air filter housing) |

| Engine Cooling System: | Initial Service – 100,000 miles/5 years Subsequent Service – 45,000 mile/3 years (Motorcraft Gold Engine Coolant) |

| Replace Automatic Transmission Fluid & Filter: | 30,000 miles |

| Replace Manual Transmission Fluid: | 60,000 miles |

| Replace Transfer Case Fluid: | 150,000 miles under normal operating conditions 60,000 miles under severe duty conditions |

| Replace Front Differential Fluid (4×4) | 100,000 miles under normal operating conditions 30,000 miles under severe duty conditions |

| Replace Rear Differential Fluid | 100,000 miles under normal operating conditions 30,000 miles under severe duty conditions |